January Issue –

We start the new decade off with a wave of realizations from OSHA and the EPA. After having finally realized the detrimental effects abrasive blasting and chemical cleaning has on life expectancy and work place conditions, laser cleaning is becoming a more viable and necessary option as a regular manufacturing standard. This January issue shares the newest regulations from OSHA and EPA regarding paint, abrasives, and solutions available today.

Having issues viewing this email? View in browser.

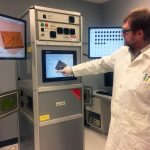

| Improve Corrosion Resistance & Adhesive Properties Of SteelWorrying about preparing metal surfaces for welding, which requires the right power tool, abrasive, and a lot of elbow grease, is a problem of the past. Even degreasing metals or removing anodized surfaces prior to further processing can now be a simple task. The CleanTech laser systems remove coatings, contaminants, and residues with the use of high-energy fiber laser sources, the same type of power source found in the company’s laser cutting and marking systems. |

| What Laser Power Do I Need?Whether you are exploring laser cleaning, laser cutting, laser engraving, or laser marking, the question back will always be ‘at what speed do you need the job done?” Laser power is directly related to speed. Low laser power, slower processing. High laser power, faster processing. The application and materials used as well will have a factor in what bottom line laser power you will need. Confusing? No worries, this is our expertise of over 100 years of combined experience and we’re happy to help point you in the right direction. Give us a call or send us your project details. Spending hours researching can be dwindled down to minutes by speaking with an expert who has devoted their lifes work to understanding this industrial process. |

Missed the Previous Issue? Topics available below:

Systems And Sampling Available

About Laser Photonics

Make The Right Decision, Consult With Laser Photonics First

Laser Photonics Executive Offices & Manufacturing Facility 1101 N Keller Rd, Suite G, Orlando, Florida 32810 | Office: 407-804-1000 E-mail: [email protected] Web: http://www.laserphotonics.com |

Unsubscribe | Update Preferences

To ensure that you continue receiving our emails, please add [email protected] to your address book or safe list.

Copyright © 2019 {CONTACT_NAME}, All rights reserved.

Laser Photonics Corporation, 1101 N Keller Rd Suite G, Orlando Florida 32810

Laser Cleaning

Laser Cleaning

Laser Marking

Laser Marking

Laser Engraving

Laser Engraving