"Smooth Sailing, Crafted with Laser Precision: Innovating Boat Manufacturing"

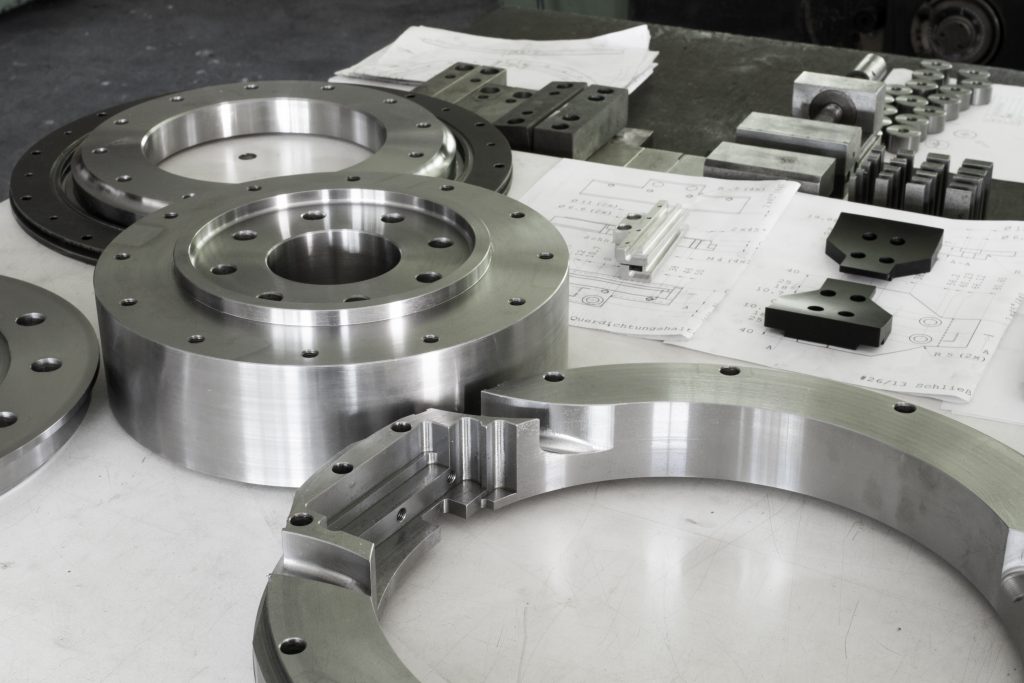

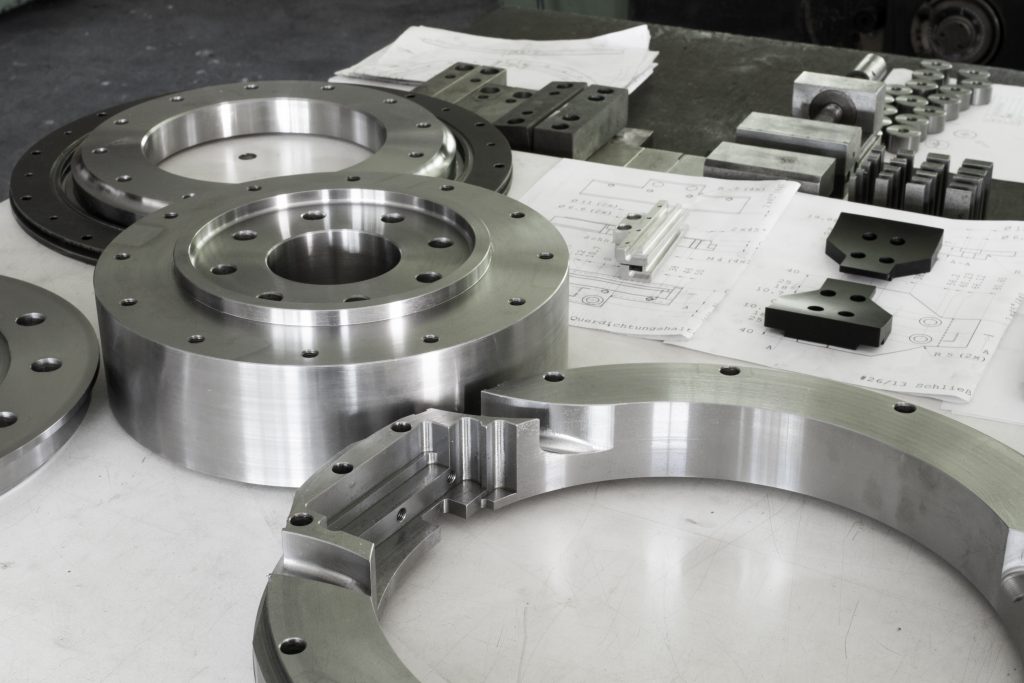

Pre and Post Weld Cleaning in the Boat Manufacturing industry

In the boat manufacturing industry, the use of lasers for post and pre-weld cleaning has revolutionized the fabrication process. With their precise and efficient capabilities, lasers have become indispensable tools in ensuring the highest quality standards.

In the pre-weld stage, lasers are utilized to remove contaminants, such as oils, rust, and paint, from the surfaces of metal components, creating an optimal bonding environment. Post-weld, lasers are employed to eliminate welding spatter, slag, and other imperfections, resulting in clean and smooth weld joints. This laser-based cleaning method not only enhances the structural integrity and longevity of boat components but also reduces manual labor, increases productivity, and minimizes environmental impact by eliminating the need for harsh chemicals.

Overall, the integration of laser technology in post and pre-weld cleaning has significantly elevated the efficiency and precision of the boat manufacturing process.

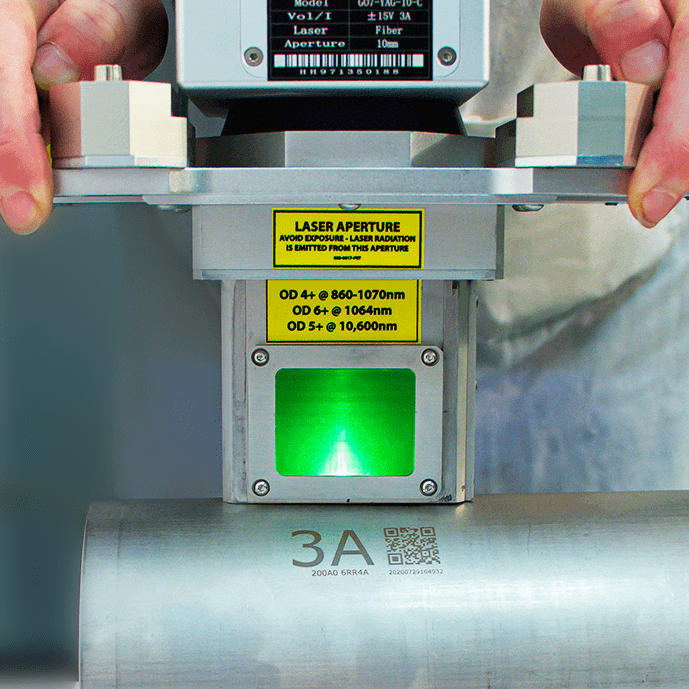

Laser Marking for Parts Identification

Lasers have emerged as invaluable tools for parts identification, revolutionizing the production process. With their high precision and speed, lasers are used to mark and engrave crucial information on boat components, ensuring traceability and facilitating efficient assembly.

By employing laser technology, manufacturers can permanently etch serial numbers, part codes, logos, and other crucial identifiers onto various materials, including metal, plastic, and composites. This enables seamless part tracking throughout the manufacturing and supply chain, simplifying inventory management, quality control, and maintenance procedures.

The laser-based parts identification process ensures clear and durable markings that withstand environmental conditions, enhancing reliability and safety.

To summarize, the integration of laser technology in parts identification has streamlined operations, improved product traceability, and elevated the overall efficiency of the boat manufacturing industry.

Display and backlit button manufacturing using lasers

Lasers have become an essential tool for manufacturing display panels and backlit buttons, revolutionizing the design and functionality of boat control systems. Laser technology enables precise and intricate cutting, etching, and engraving of various materials, such as acrylic, glass, and metal, to create visually appealing and highly functional user interfaces.

Laser-cutting allows for precise shaping of display panels, ensuring seamless integration into the boat’s control panel design. Additionally, lasers can etch backlit buttons with precise symbols, labels, and indicators, enhancing visibility and user-friendliness in low-light or nighttime conditions.

The use of lasers in display and backlit buttons manufacturing ensures durable and long-lasting markings that resist fading and wear. This advanced manufacturing process offers boat manufacturers the ability to create custom, aesthetically pleasing control systems that enhance user experience and promote efficient operation.

Selective repair of powder-coated parts

Laser technology has revolutionized the boat industry by providing a highly precise and efficient solution for selectively repairing powder-coated components. Powder coating is a popular method for providing a protective and decorative finish to boat components. However, when these coated parts suffer damage or imperfections, traditional repair methods can be time-consuming and labor-intensive. Laser technology, on the other hand, allows for targeted and controlled removal of damaged or flawed areas without affecting the surrounding coating.

By precisely focusing the laser beam, boat manufacturers can remove the damaged powder coating layer and prepare the surface for a seamless repair. The laser selectively ablates the damaged material, leaving the intact coating intact, minimizing the need for extensive reapplication or rework. This laser-based selective repair process not only saves time and reduces material waste but also ensures a high-quality and aesthetically pleasing finish, thereby increasing the efficiency and sustainability of boat manufacturing.