Laser Cleaning in the Nuclear Industry

Nuclear Decontamination Solution

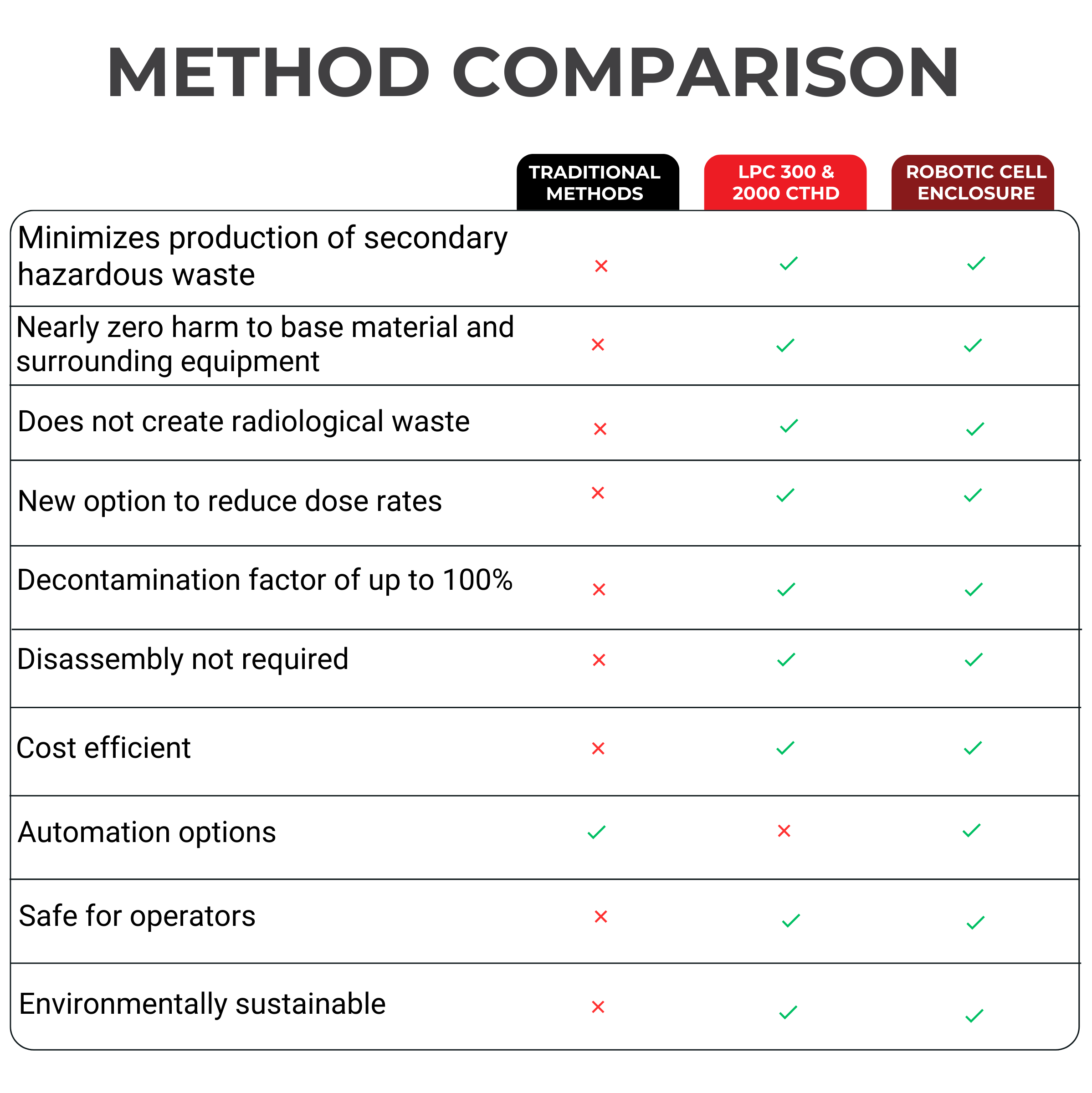

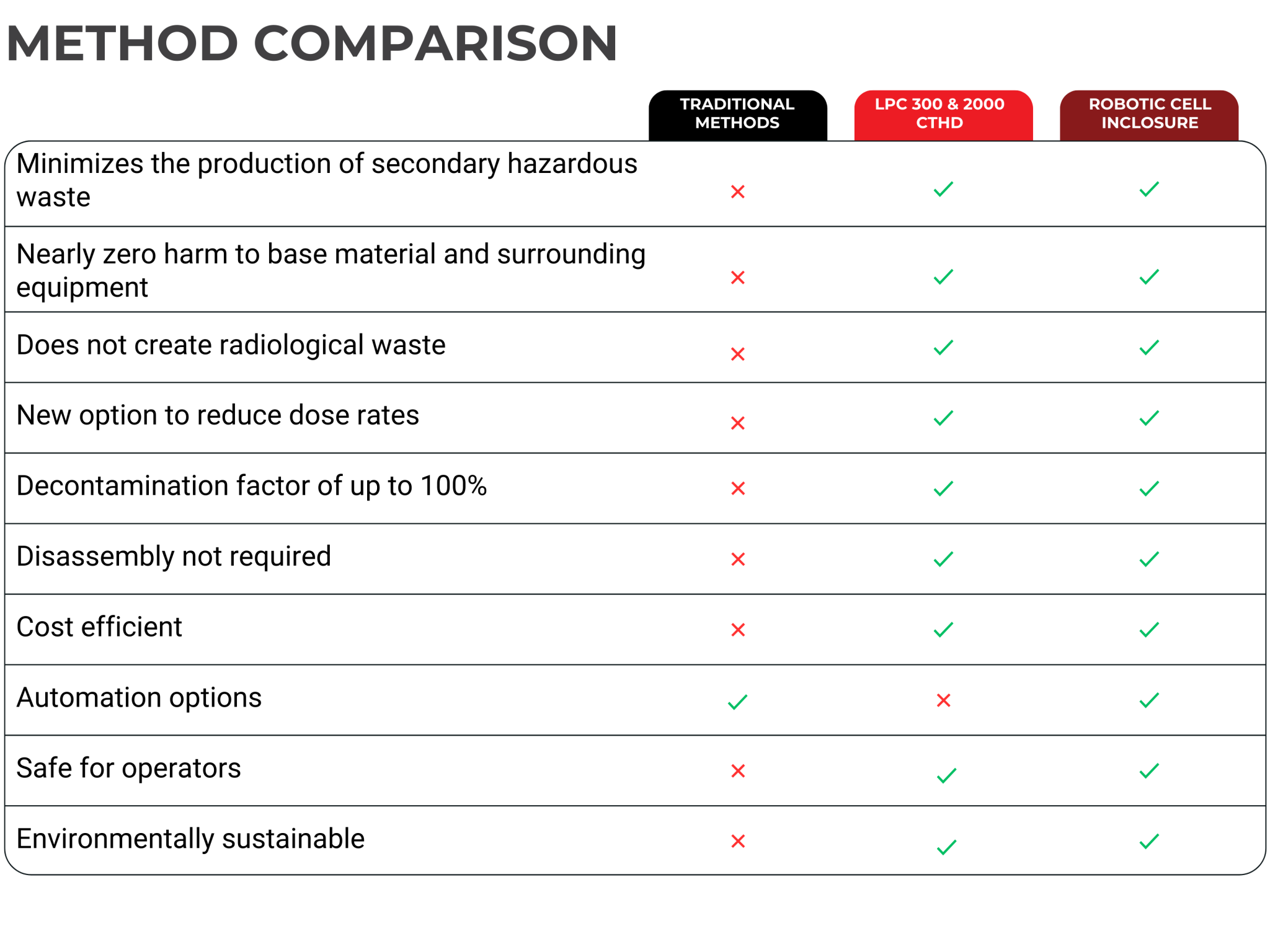

Laser Cleaning in the Nuclear Industry: Laser cleaning is a safe, eco-friendly, and cost-effective method of nuclear decontamination. This allows industry professionals to effectively treat contaminants during nuclear decommissioning.

Key Advantages:

- Precision: Laser cleaning is precise and accurate, allowing for the effective treatment of targeted surfaces.

- Non-Destructive: The process is non-contact, preventing physical damage to worked-on material.

- No Secondary Waste: Laser cleaning produces minimal waste, making it environmentally friendly.

- Operator Safety: Laser cleaning eliminates the need for hazardous consumables that harm the health of operators.

- Automation: The technology can be automated, further enhancing efficiency while reducing the need for manual labor.

- Customization: Laser cleaning technology can be tailored to fit the unique needs of operators regardless of the industry or application.

Laser cleaning technology offers a safe, effective, and innovative solution to nuclear decontamination, facility and turbine maintenance, addressing the challenges posed by traditional cleaning methods and contributing to safer and more efficient nuclear facility maintenance.

Scientifically Proven to Benefit your Facility

Step by Step Process of How To Execute Laser Cleaning:

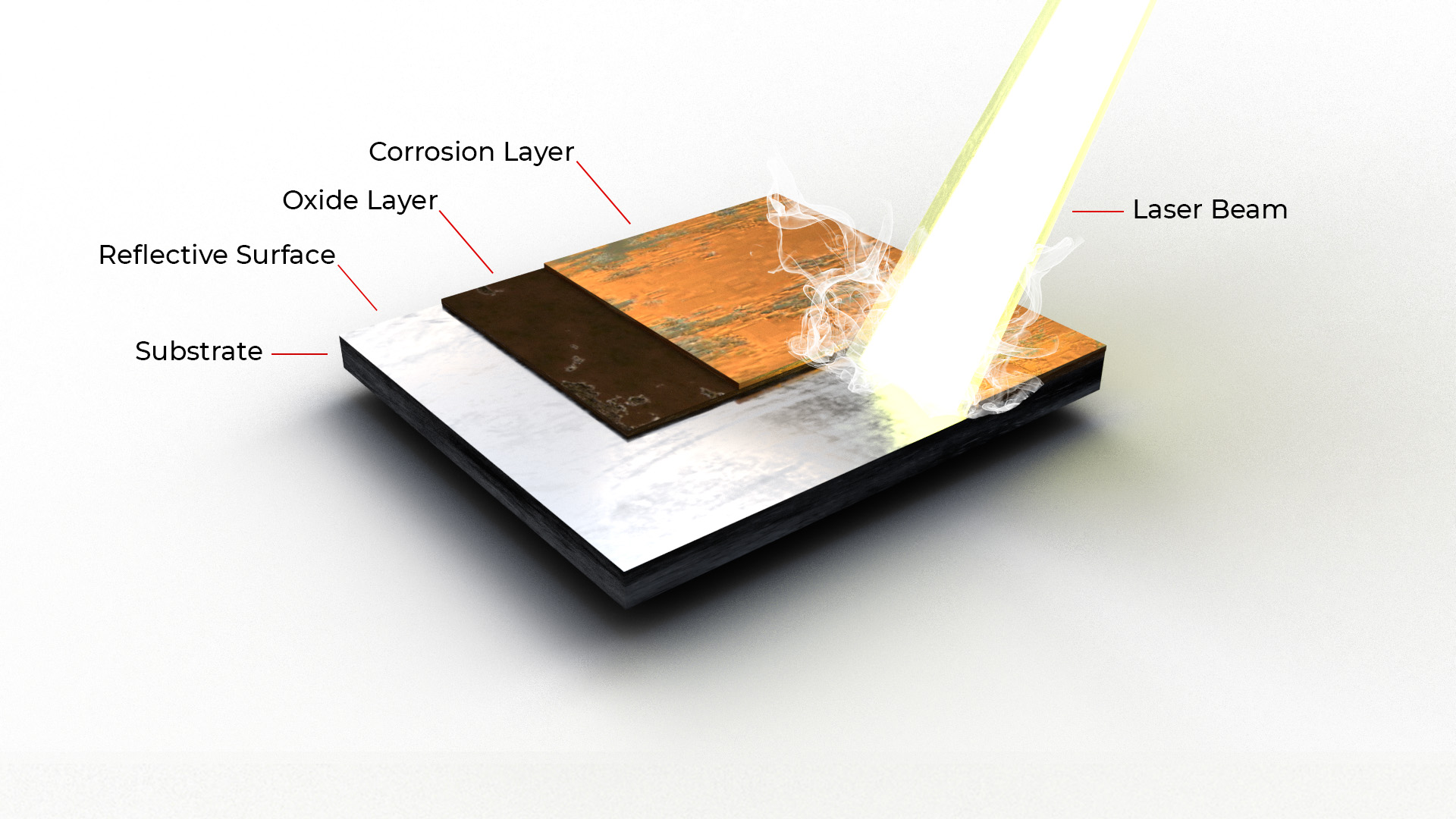

- Selection of Laser Parameters: Engineers and technicians select the appropriate laser system based on several factors, which include the type of contaminant, the material of the surface, and the desired level of cleaning.

- Laser Absorption: The selected laser emits a high-intensity light directed onto the contaminated surface. The result is the energy from the laser being absorbed by the contaminated layer.

- Energy Transfer: The absorbed energy causes the contaminant layer to heat up rapidly. This results in the energy being transferred from the laser to the contaminants, causing the layer to vaporize or turn into a plasma state.

- Contaminant Removal: As the contaminants vaporize or turn into a plasma state, they detach from the surface. This process is known as ablation. The vaporized contaminants are carried away by the surrounding gas or are extracted through an integrated exhaust system.

- Surface Integrity: Laser cleaning is a precise process that selectively targets contaminants while leaving the underlying surface mostly unaffected. The energy is absorbed by the contaminants rather than the substrate material, minimizing damage to the surface.

- Collection and Disposal: The vaporized contaminants are collected, filtered, and safely disposed of using appropriate procedures to prevent pollution.

Who We Help

Laser cleaning is proving to be a game-changer for companies in the nuclear industry, offering a range of benefits that address their specific needs and challenges. Here’s how we have helped many big-name companies in the industry such as GE, NASA and more.

- We have reduced their down time with our technology; allowing them to resume operations more quickly and maintaining consistent power generation.

- We have saved them money and time by removing the need for disassembly and reassembly of components also contributing to lower maintenance costs.

- We have increased operational efficiency through our laser technology ensuring that equipment and components operate at their optimal performance Clean surfaces contribute to smoother operations and increased power output.

- We have improved safety, efficiency and environmental responsibility while adhering to regulatory standards, contributing to long-term profitability and sustainability of nuclear This has enabled the companies we work with to maximize their return-on-investment while ensuring safe and reliable operations.