LASER CLEANING

How It Works

How It Works

Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted material.

Your Top Choice for Surface Preparation

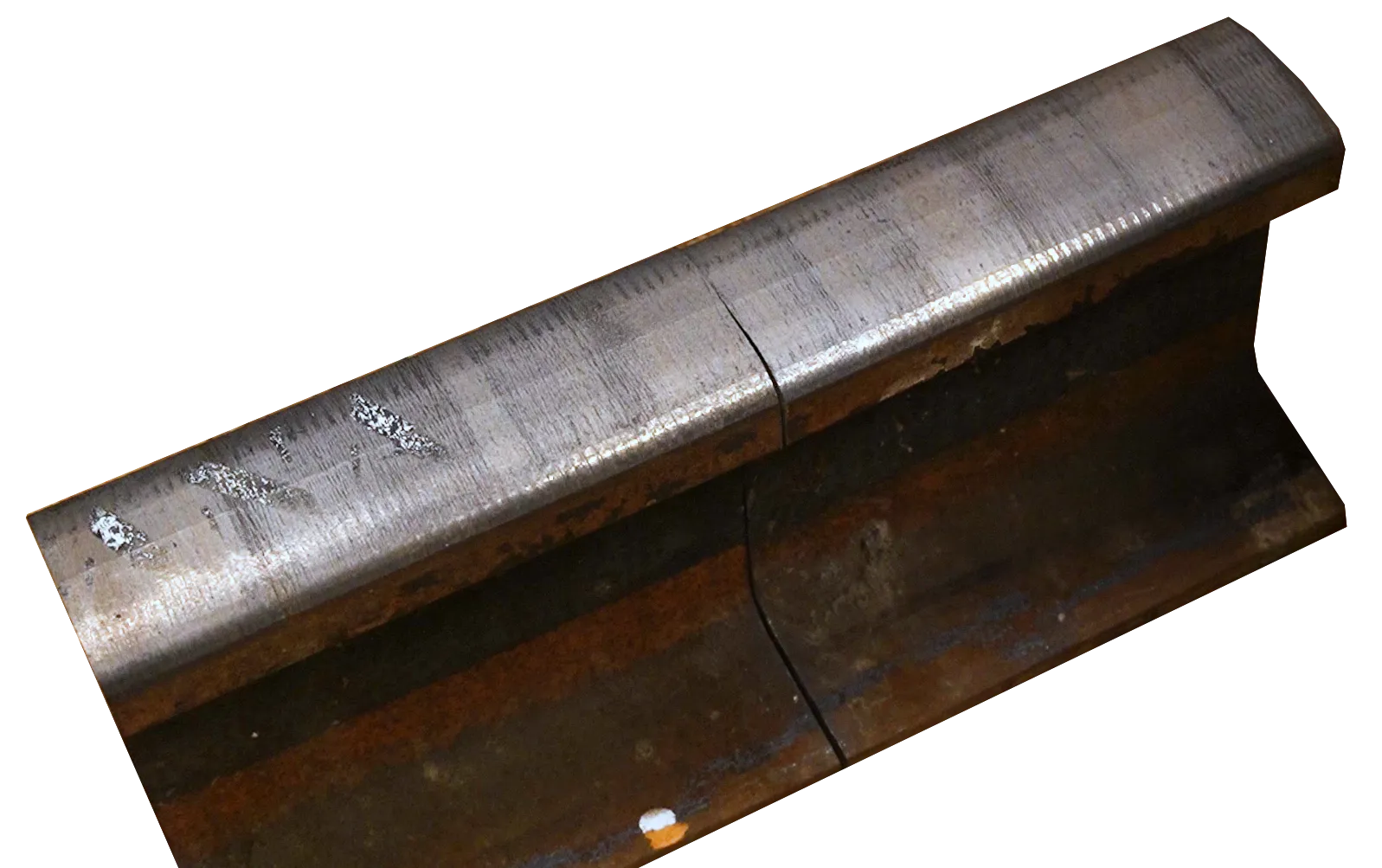

Laser cleaning removes coatings and contaminants like rust while leaving the underlying substrate intact. If you are looking for a deep clean, precision, and time efficiency while also ensuring environmental responsibility and human safety during your operation, laser cleaning is the solution for you.

Your Top Choice for Surface Preparation

Laser cleaning removes coatings and contaminants like rust while leaving the underlying substrate intact. If you are looking for a deep clean, precision, and time efficiency while also ensuring environmental responsibility and human safety during your operation, laser cleaning is the solution for you.

Finishing

Lasers

Finishing Lasers

Conditioning

Lasers

Conditioning Lasers

Roughening

Lasers

Roughening Lasers

What is Silicosis?

According to the American Lung Association, silicosis is caused by breathing in silica, a mineral found in sand, glass, and other rock-type materials. These materials are often used as abrasive additives in sandblasting. When propelled at high speeds onto a surface for cleaning, silica particles become airborne, posing health risks for sandblasting workers and others present. Prolonged inhalation of silica dust can cause lung inflammation and, over time, lead to scar tissue formation called pulmonary fibrosis. This damage to the lungs is irreversible, though therapies can slow down the progression of the disease. Mild symptoms include coughing and shortness of breath. Complications include tuberculosis, lung cancer, chronic bronchitis, autoimmune disorders, and kidney disease.

While laser cleaning is much safer than traditional industrial cleaning methods like sandblasting, certain protective measures must be taken while operating the machinery. Be sure to protect yourself and those in your vicinity if you process a surface that contains hazardous particles like silica or lead.

Source: https://www.lung.org/lung-health-diseases/lung-disease-lookup/silicosis

Want To See It in Action?

Experience firsthand the innovation that drives our products by booking a personalized demonstration at our state-of-the-art Customer Experience Center. Explore our cutting-edge technology and discover how our solutions can transform your business.

Reserve your spot now!