Galvo Auto focusing System

Galvo Auto focusing System

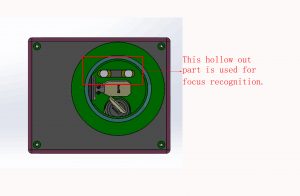

The Autofocusing system is made up of a distance measurement module, stepping motor, stepping motor driver, control card and buttons. The distance measure module is used to detect the distance between galvo scanner head and the object down; Stepping motor is used to adjust the height of the galvo scanner; The buttons include Up, Down and Auto Focus. Control card controls the operation of the whole system.

The Galvo Autofocusing system realizes the transform from hand focusing to autofocusing, not only save the manpower and material resource but also greatly improve the accuracy of the focusing.

Lens Attachment Diagram

Autofocus precision can achieve 0.1mm,measure range is 120mm-280mm, the system is equipped with alarm light and tone, when the object is not in the measurement, the control board indicator light is on and the buzzer alarm, then, through manual pressing button of moving up or down to move galvo scanner, which the object can be within a measuring range and the system will stop the alarm. The control board provides an alarm signal extension port, and the customer can receive the alarm signal externally according to the requirement. The automatic focusing system is increased the acceleration and deceleration process at the beginning and end of the moving process, which reduces shocking on the moment of starting or stopping. The moving speed can be set or change the moving by software.

Benefits:

- Reduced processing times

- Increased throughput

- Reduced operator fatigue and error

Features:

- Double Red Light Positioning

- Quality Scanning Galvanometer

3D Dynamic Focusing System

3D Dynamic Focusing System