CleanTech™ Class I Laser Systems

Class I laser products contain more powerful, higher class lasers that need to be enclosed to make them safe. Our Class I lasers are installed in an enclosure, with safety viewing glass, and safety interlock features.

Unsure which system is right for you? Learn how to choose the right laser blaster

CleanTech™ Titan FX

The CleanTech Titan FX is a high-power, large format laser designed for cleaning, rust removal, and surface conditioning on large and heavy pieces.

Applications:

- Designed for industrial applications

- Used for cleaning, rust removal, and surface conditioning

- Up to 7′ x 13′ processing area

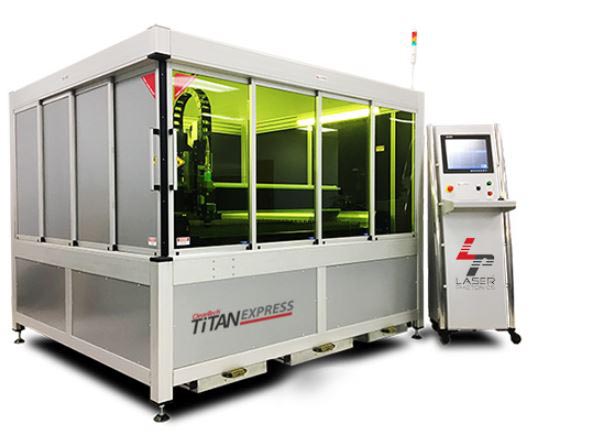

CleanTech™ Titan Express

Mid-Size – Powerful – Complete. The CleanTech Titan Express Laser Cleaning Machine is a high-power fiber laser for cleaning and surface conditioning.

Applications:

- Rust and paint removal, and casting mold cleaning

- Used for cleaning and surface conditioning

- Up to 4′ x 4′ working envelope

- Class IV Fiber Laser

CleanTech™ Laser Blaster Cabinet

The CleanTech Laser Blaster Cabinet system is the only laser cleaning machine in the world that incorporates the exclusive power of a fiber laser with a handheld laser blasting head inside an enclosed 30” x 26” work area.

Applications:

- Cosmetic surface conditioning (replaces bead blasting)

- Customizable with anywhere from a 50-Watt finishing class fiber laser to a 300-Watt conditioning class fiber laser.

- Selective paint Removal

- Mold Cleaning

- Joining pre-treatment, Pre-Welding

CleanTech™ MegaCenter

The CleanTech™ Megacenter Laser Cleaning System is an Industrial-Grade Laser parts cleaning, rust removal and surface conditioning system

Applications:

- Industrial-Grade Laser System

- Used for parts cleaning, rust removal and surface conditioning system

- Operates as a standalone unit or can easily be integrated into a production line environment