Seaworthy Laser Systems

Endure the high seas with the help of laser technology. Upgrade your ship maintenance and manufacturing capabilities using our maritime-focused laser solutions.

Seaworthy Laser Systems

Endure the high seas with the help of laser technology. Upgrade your ship maintenance and manufacturing capabilities using our maritime-focused laser solutions.

Applications

What We Offer

Laser Cleaning Systems

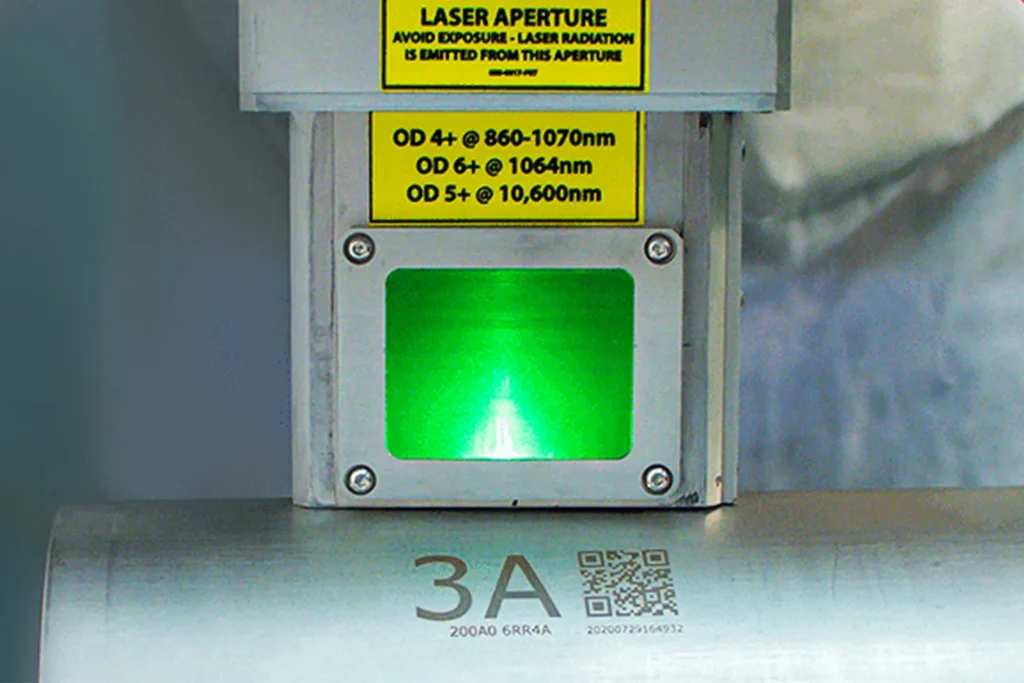

Laser Marking Systems

Laser Cutting Systems

Laser Welding Systems

Case Studies & News

Laser Photonics Announces Upcoming Maritime Roadshow

The Laser Photonics Roadshow Team Will Visit Florida Boating Devotees and Industry Professionals To Boost Brand Recognition, Lead Generation & Laser Technology Awareness

Revolutionizing Marina Operations with the MARLIN Laser Cleaning System

Neglecting required maintenance can lead to significant corrosion, resulting in costly repairs and unsafe conditions for boat owners and their guests. The MARLIN gives you the added benefit of being able to also maintain your facility and tools as well.

Laser Photonics Corporation Announces First of Its kind Maritime Laser Cleaning Commercial

Laser Photonics Corporation Announces First of Its kind Maritime Laser Cleaning Commercial ORLANDO, Fla., Nov. 6, 2023 – Laser Photonics Corporation (NASDAQ: LASE) ("LPC"), a leading global industrial developer of CleanTech laser systems for laser cleaning and other...

Laser Photonics to Showcase Its Line of Maritime Laser Cleaning Solutions at Upcoming International WorkBoat Show

Laser Photonics to Showcase Its Line of Maritime Laser Cleaning Solutions at Upcoming International WorkBoat Show ORLANDO, Fla., Oct. 31, 2023 – Laser Photonics Corporation (NASDAQ: LASE) ("LPC"), a leading global industrial developer of CleanTech laser systems for...

Want To See It in Action?

Experience firsthand the innovation that drives our products by booking a personalized demonstration at our state-of-the-art Customer Experience Center. Explore our cutting-edge technology and discover how our solutions can transform your business.

Reserve your spot now!