Lasers and The Global Automotive Industry

To start our timeline laser use in automotive manufacturing dates back to Ford Motor Co in the mid ’70s. Lasers were used initially for underbody welding for an assembly line. Today, lasers are used in nearly every facet of the automotive industry.

Learn More: https://www.laserphotonics.com/industries/automotive

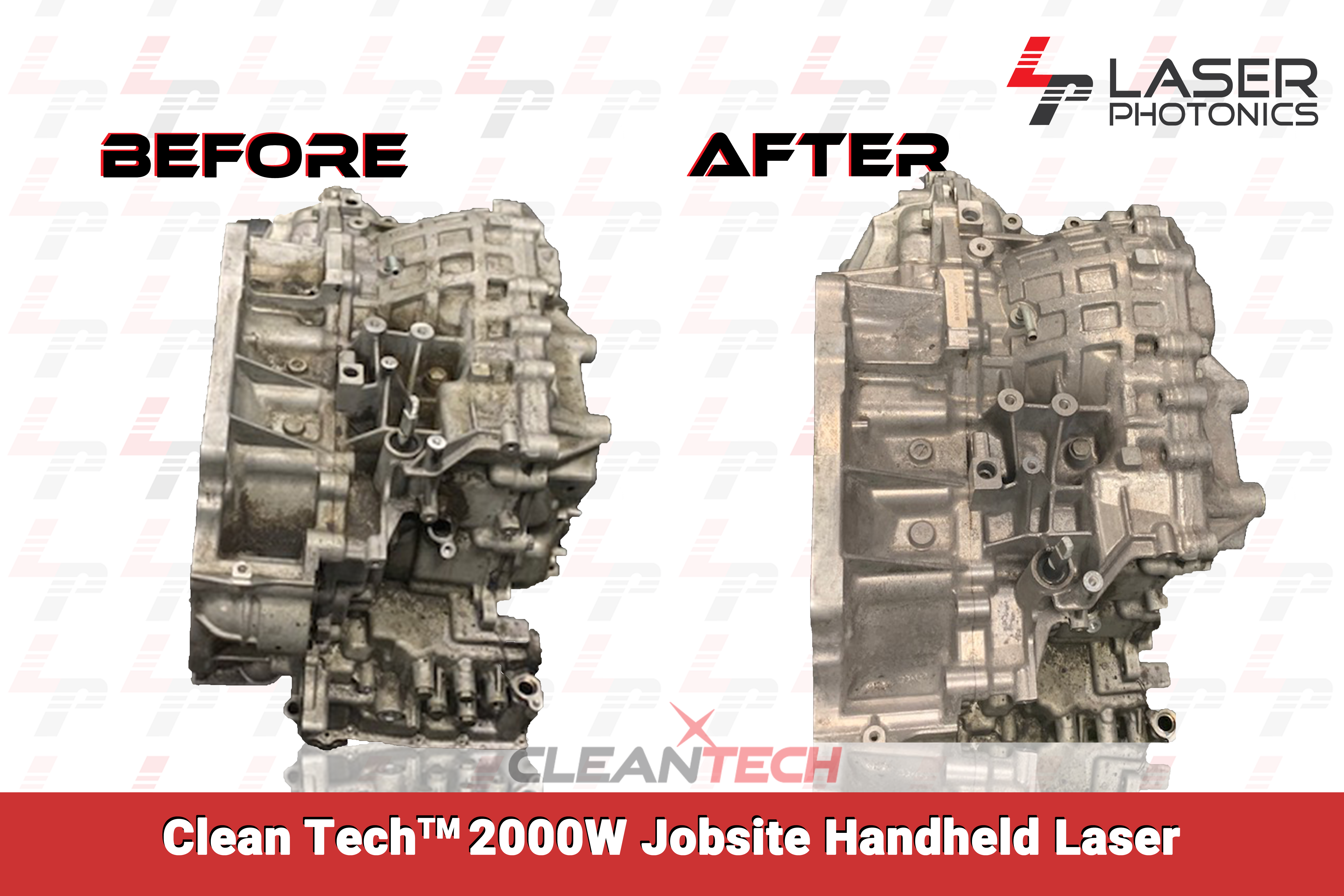

Now with traditional transmission cleaning methods with the use of industrial cleaners and degreasers are extremely labor and time intensive. With the future upon us we are updating these methods to more effective ways. Using the new CleanTechTM 2000w laser you will experience the laser beam hits the aluminum surface, grease, oil, dirt and aluminum oxides are all vaporized into dust and fumes. This laser sends the right amount of energy to remove those contaminants without introducing impurities in the aluminum and metals.

Automotive Manufacturing Applications

Beyond metal cutting and welding, auto manufacturers are upgrading to laser cutting for vehicle sealing, custom luxury seats, interior components, airbags, and perforating fabric. The auto industry is also utilizing CleanTechTM laser cleaning systems (mold cleaning, part cleaning, and surface prep, automotive paint removal), 3D metal printing and engraving marking (UID marking, barcoding, backlit panels/switches, glass marking, ablation, etching, marking, and more.

Finally our goal is to provide manufacturing customers with a faster, safer method of cutting, engraving, marking, and cleaning that can be repeated and operated 24-7. Solutions that will reduce operating cost and generate ROI by fulfilling more orders – faster.

Why upgrade underperforming equipment to innovative laser systems from Laser Photonics?

1. Reduce cost of operation: low power consumption limited to no maintenance

2. Unmatchable speed, accuracy, and precision

3. Ability to easily cut almost any material – especially highly reflective metals

4. No additional learning curve – CNC controls with G-Code programming

5. Longest lasting lasers of any type

6. Expandable: from 2” x 2”, robot arms, 6’ x12’ large format table to custom sizes

7. Safe, easy to operate and 24/7 365 operating longevity

Laser Cleaning Applications:

| Laser Ablation | Laser Cleaning | Paint Stripping | Surface Texturing |

| Surface Conditioning | Pre-Adhesion Treatment | Mold Cleaning | Pre-Weld Preparation |

| Post-Weld Treatment | Degreasing | Rust Removal | Corrosion Removal |

| Mold Cleaning | Zinc Removal | Anodization Removal | Oxide Removal |

To discuss your potential laser cleaning application, Contact Laser Photonics, 407-804-1000, or fill out our contact form to be contacted by a laser expert.

About Laser Photonics Corporation

Laser Photonics is the leading industrial Brand in high-tech laser systems for laser marking, laser cutting, laser engraving, and other material processing applications. Our systems are currently and historically used by manufacturers in the automotive, aerospace, industrial, defense, electronic, semiconductor, flat panel, and medical industries around the world. The Laser Photonics Brand of products is associated with a number of worldwide licenses and patents for innovative and ‘unique to the industry’ laser products and technologies.

Laser Photonic’s brand history is associated with better throughput, higher quality, and low cost of ownership for each of our products. We are raising the standards and working toward making everyone’s life simpler through each laser application. The Brand has, for more than 2 decades, been the industry standard workhorse of laser subtractive material processing for such world-renowned companies such as Sony, NIKE, 3M, Delphi, NNSY-Norfolk Naval Shipyard, NASA, Cannon Air Force Base, Eaton Aerospace, GE, Caterpillar, Harley-Davidson, PPG, Eli Lilly, Smith & Nephew, Millipore, DuPont, Bosch, Gables Engineering, Champion Aerospace, Smith Aerospace, Metaldyne, Dupont and Heraeus. The present license holders are committed to continue the legendary performance of Laser Photonics Brand Equipment and provide award-winning support to its past, present, and future customers.