Laser Photonics (LP) has developed a laser characteristics matching system that sets standards for measuring the performance of industrial laser materials processing equipment. This industry first is designed to take the mystery out of choosing the right laser to achieve desired results in industrial materials processing.

By Mark Kouri

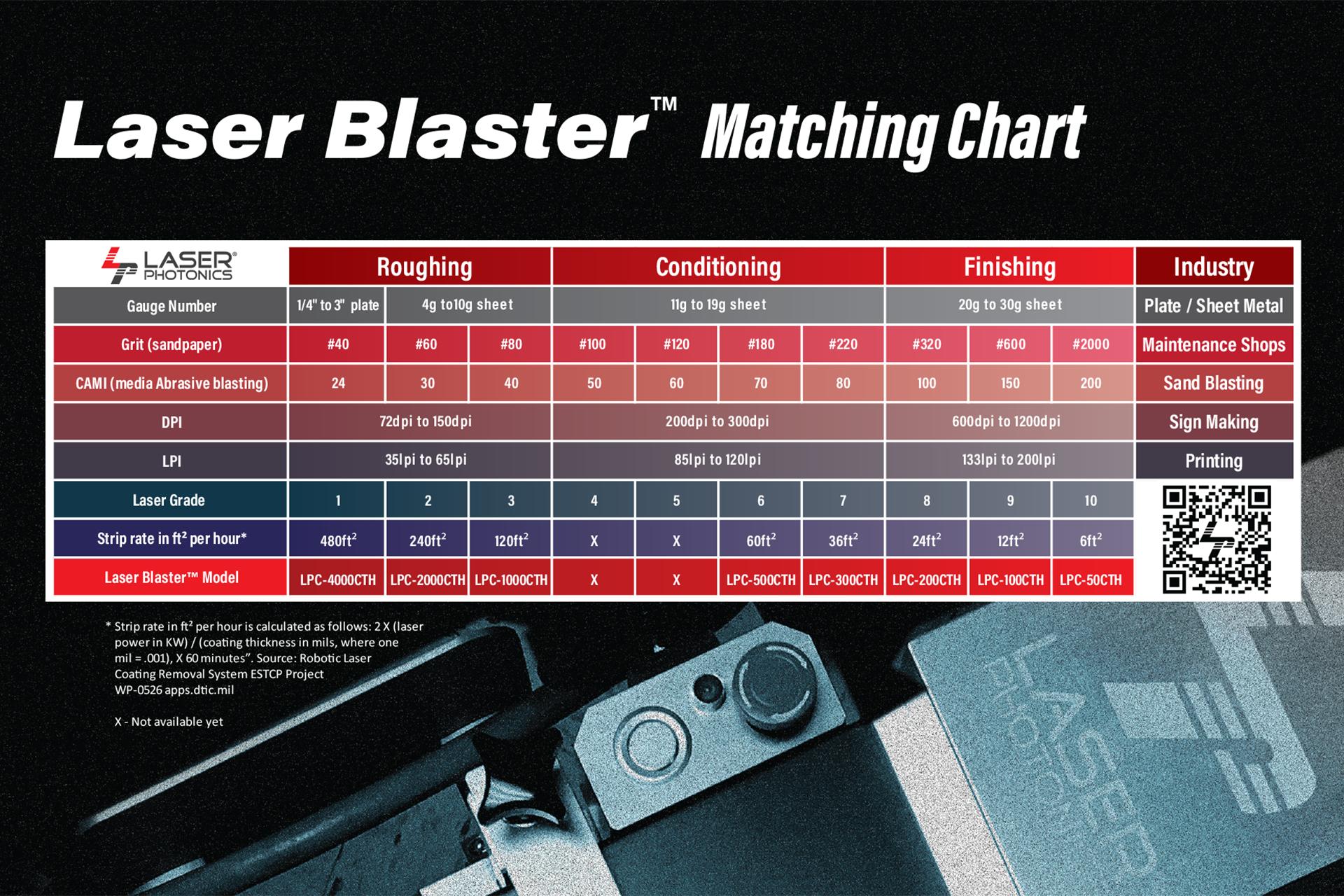

Sandpaper and abrasives blasting media are graded by grit size, sheet metal is measure by gauge, desktop printers are categorized by DPI, and the printing industry uses LPI to determine the resolution of printed publications. Now that industrial lasers are increasingly replacing hazardous legacy materials surface preparation and industrial cleaning methods, the laser photonics industry as a whole has recognized the need for a grading standard to apply to lasers.

Without a standard, buyers have typically relied on the stated wattage of systems listed on manufacturers’ product labels to a system’s ability to achieve desired results. But since not all lasers are created equal, this can be a costly mistake. Systems billed as laser cleaning equipment are built with vastly different technologies and internal components, ranging from inefficient and shorter-lived decades-old resonator based lasers, to highly efficient state-of-the-art fiber lasers. Incorporated optics and software controllers also make a huge difference in the efficacy of a laser system. So, depending on which components are used in the construction of industrial laser equipment, one manufacturer’s laser rated at a lower wattage may actually be more efficient and have a higher throughput—or strip rate—than a competitor’s product rated at a 1000W.

So, to take the guesswork out of determining which laser system might right for a particular job, LP published an easily relatable comparison table that gives end-users from different industries a visual overlay of laser grades and the legacy industry standards that those end-users are accustomed to working with. The simple to use Laser Blaster™ Matching Chart grades lasers on a scale from 1 through 10, with 1 yielding the roughest finish, and 10 achieving the finest finishes. So by seeing where a particular grade of laser lines up with the correct gauge of steel, sandpaper grit, or CAMI rating for blasting media, one can immediately know which laser is right for the job.

Largely because of health, safety and environmental concerns, industry is under pressure to abandon legacy materials processing methods. Industrial laser systems have proven to be the clean, safe, and efficient alternative, but without clear guidance by way of a standard, adoption of the new technology has been hampered by need to take a slow and costly trial and error approach. In recognition that industry relies on standards to ensure consistency and repeatability, and in the absence any such standard for laser cleaning applications, LP took the initiative. By applying its industrial laser equipment manufacturing experience and expertise it delivered a simple, practical tool to aid anyone seeking to understand which laser to employ to achieve their desired materials processing results using laser.

The laser photonics industry has kicked this idea around for some time, but it was industrial laser pioneer LP that delivered a tool that industry can use today. That should come as no surprise. LP has developed the broadest range of industrial laser equipment available, including their CleanTech™ line, which runs the gamut from lasers that can delicately clean contaminants from sensitive materials with finesse, to the world’s most powerful handheld Laser Blasting™ systems capable of vaporizing the rust from a battleship.

LP delivers an impressive stable of products thanks to a dedicated team of experienced laser physicists, design engineers, software developers, assemblers, and sales & marketing professionals all working under one roof in Orlando, Florida in the only U.S based industrial laser equipment R&D and manufacturing facility.

About Laser Photonics Corporation

Laser Photonics is the leading industrial Brand in high-tech laser systems for laser marking, laser cutting, laser engraving, and other material processing applications. Our systems are currently and historically used by manufacturers in the automotive, aerospace, industrial, defense, electronic, semiconductor, flat panel, and medical industries around the world. The Laser Photonics Brand of products is associated with a number of worldwide licenses and patents for innovative and ‘unique to the industry’ laser products and technologies.

Laser Photonic’s brand history is associated with better throughput, higher quality, and low cost of ownership for each of our products. We are raising the standards and working toward making everyone’s life simpler through each laser application. The Brand has, for more than 2 decades, been the industry standard workhorse of laser subtractive material processing for such world-renowned companies such as Sony, NIKE, 3M, Delphi, NNSY-Norfolk Naval Shipyard, NASA, Cannon Air Force Base, Eaton Aerospace, GE, Caterpillar, Harley-Davidson, PPG, Eli Lilly, Smith & Nephew, Millipore, DuPont, Bosch, Gables Engineering, Champion Aerospace, Smith Aerospace, Metaldyne, Dupont and Heraeus. The present license holders are committed to continue the legendary performance of Laser Photonics Brand Equipment and provide award-winning support to its past, present, and future customers.