Sandblasting: is it actually affordable?

Many people in industry still believe that sandblasting is the cheapest surface treatment available. But—even without factoring in regulatory fines from OSHA and EPA that came into effect last year—that simply does not add up. There are numerous reasons that manufacturers around the world are adopting Laser Cleaning systems for corrosion control, coatings removal and surface preparation: improved occupational safety, unparalleled accuracy and precision, improved processing speed and environmental friendliness. But ultimately, businesses must prioritize their bottom line. The one cost that makes sandblasting so much more expensive is hidden: consumables. The media sprayed by sandblaster costs an average of $39.00 per hour of operation, while most machines burn through an average of $10.72 worth of diesel fuel per hour. Ultimately, the operating costs of sandblasting machinery are nearly five times those of Laser Photonics’ Laser Blasting systems. If cost is an important factor for manufacturers considering new surface preparation solutions, they should look beyond the installation costs.

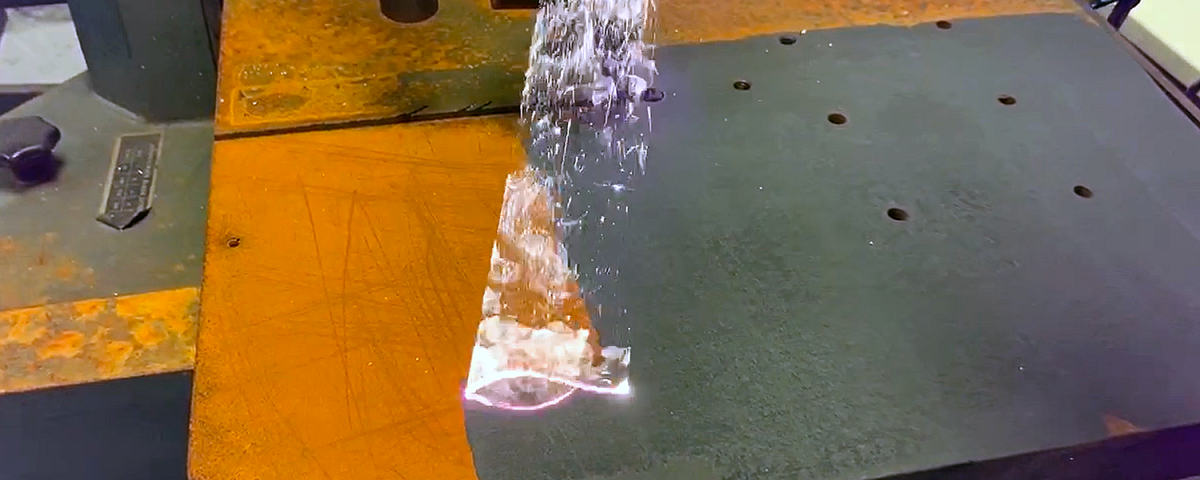

CleanTech Laser Blasting is the disruptive technology developed by Laser Photonics that has already replaced hazardous blast media and chemical cleaning methods for Fortune 500 companies, global industries and industrial agencies. Sandblasting has been around since the nineteenth century. It is known to cause lung cancer, silicosis and hearing loss. Laser Blasting is revolutionizing how industrial cleaning is carried out, and Laser Photonics is leading the way with its safe, clean and economical line of revolutionary cleaning products. Want to see how our systems can process your own materials and components? Fill out the form below to coordinate a sample with our Application Testing & Research Lab.

About Laser Photonics

Laser Photonics Corporation, based in Orlando, Florida, is the leading industrial company in high-tech laser systems for laser cleaning, laser marking, laser cutting, laser engraving, 3D printing, and other materials processing applications. Our systems are—currently and historically—used by manufacturers in the aerospace, automotive, defense, energy, industrial, maritime, and medical industries around the world. The Laser Photonics brand is associated with a number of worldwide licenses and patents for innovative and ‘unique-to-industry’ laser products and technologies.

The brand has, for over three decades, been the workhorse of industry-standard laser subtractive manufacturing. Laser Photonics systems have been implemented into the production and maintenance regimens of world-renowned organizations such as Sony, NIKE, 3M, Delphi, NNSY-Norfolk Naval Shipyard, NASA, Cannon Air Force Base, Eaton Aerospace, Blue Origin, GE, Caterpillar, Harley-Davidson, PPG, Eli Lilly, Smith & Nephew, Millipore, DuPont, Bosch, Gables Engineering, Champion Aerospace, Smith Aerospace