Almost every laser manufacturer in the market categorizes their laser systems by their power.

Whether a laser is powered by 50 watts or 4 kilowatts, its power consumption by wattage is not the best indicator of the materials processing results it achieves. If that was the case, then there would be no difference between the 2-kilowatt laser cleaning handhelds we manufacture and those made by our competitors. However, not all lasers are created equally. The type of beam emitted by the laser source, the beam’s configuration settings for the specific application it is processing and the overall efficiency of the system all impact a given laser cleaning system’s results as much as—if not more than—its power consumption.

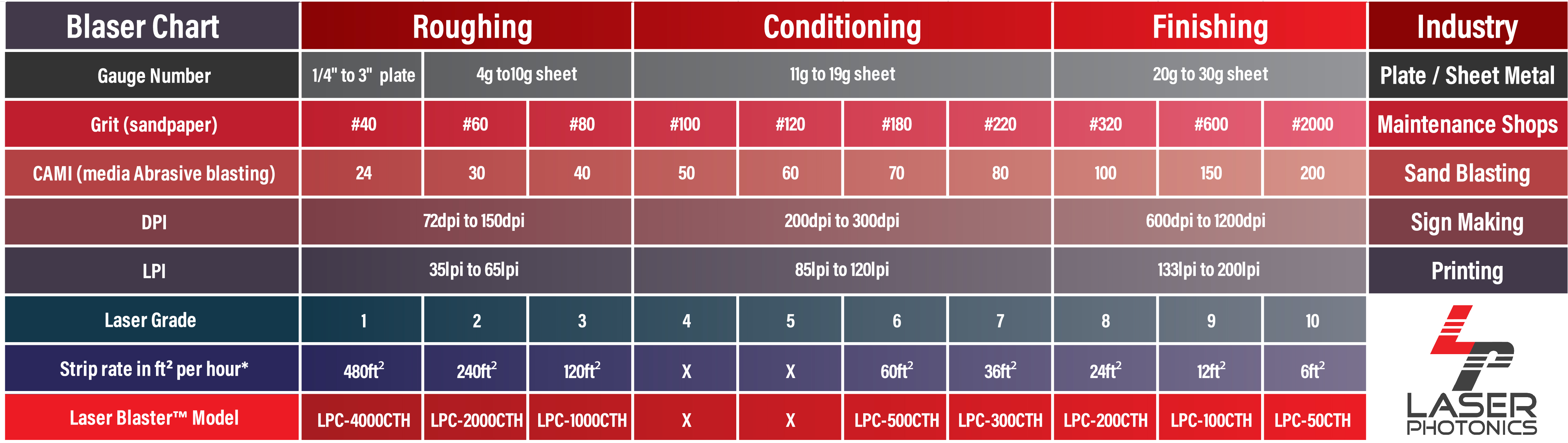

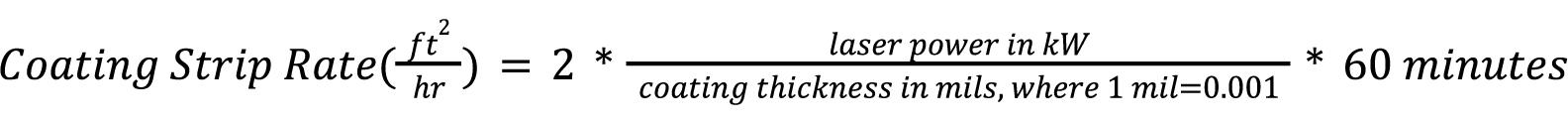

The most important measurement that should be used for classifying a laser cleaner’s performance capability is its Coating Strip Rate in ft2 per hour. This can be calculated as follows:

After all, laser machinery’s end-users don’t care about how much power they consume. Their primary concern is how well a given laser can complete a surface preparation project, and, how fast they can do it. Laser Photonics builds advanced industrial laser systems using state-of-the-art components. This includes the world’s most powerful handheld laser cleaning systems, as well as the most precise. In fact, a Laser Photonics laser cleaning system of lower wattage can outperform less efficient competing systems of higher wattage; so, power consumption alone is not a good gauge of performance.

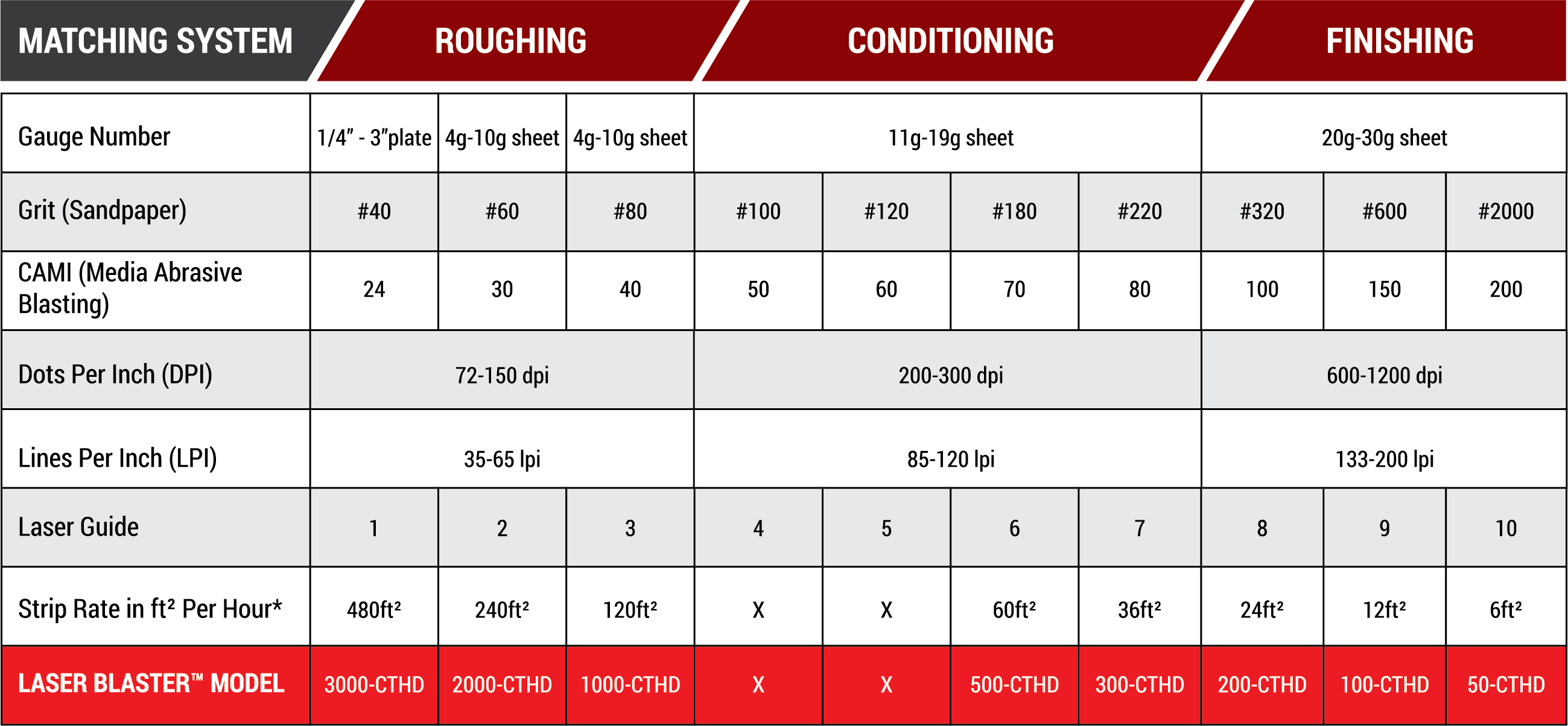

That’s why we have organized our laser cleaning systems into three different classes—based upon the intensity (and the kind) of surface preparation they can perform, as well as their Coating Strip Rate. This infographic was developed to help consumers determine a relatable method of comparison for the surface preparation capabilities of the CleanTech handheld line of cleaning lasers. A breakdown of the three classes of lasers is summarized below it.

CleanTech™ Roughing Lasers

CleanTech Handheld LPC-3000-CTHD

CleanTech Handheld LPC-2000-CTHD

CleanTech Handheld LPC-1500-CTHD

CleanTech Handheld LPC-1500-CTHS

CleanTech Handheld LPC-1000-CTHD

CleanTech Handheld LPC-1000-CTHS

These systems are suited for quick removal of thick layers of contamination or chemical debris (like bulk rust or thick coating removal). These high-powered fiber-laser systems emit continuous, focused laser beams. With Coating Strip Rates ranging from 120 to 280 ft2 per hr., these laser systems handle larger jobs with ease and produce a rougher, coarse finish to the surface substrate. In layman’s terms, Roughing Class Lasers’ processing capabilities are most easily compared to:

- ¼ ” to 10g Sheet Metal Gauge Numbers for Metal Fabricators

- #40 to #80 Sandpaper Grit for Maintenance Shops

- 24 to 40 US CAMI Grit for Abrasive Blasting Contractors

- 72 dpi to 150 dpi for Sign Makers

- 35 lpi to 65 lpi for Printing

CleanTech™ Conditioning Lasers

CleanTech Handheld LPC-300-CTHD

CleanTech Conditioning Laser Cleaning Systems use pulsing fiber laser systems to pack more of a punch than their counterparts in the Finishing Class. With Coating Strip Rates ranging from 36 to 60 ft2 per hr., these laser cleaning machines are the best solutions for larger jobs with longer lead times, or smaller projects with shorter time constraints. Conditioning Laser Systems are the middle ground between Roughing and Finishing Class CleanTech lasers. In layman’s terms, Conditioning Class Lasers’ processing capabilities can be most easily compared to:

- 11g to 19g Sheet Metal Gauge Numbers for Metal Fabricators

- #100 to #220 Sandpaper Grit for Maintenance Shops

- 50 to 80 US CAMI Grit for Abrasive Blasting Contractors

- 200 dpi to 300 dpi for Sign Makers

- 85 lpi to 120 lpi for Printing

CleanTech™ Finishing Lasers

CleanTech Handheld LPC-200-CTHD

CleanTech Handheld LPC-100-CTHD

CleanTech Handheld LPC-50-CTHD

While Roughing Lasers can remove the bulk of coatings and contaminants from nearly every surface, cleaning the last few layers of material on metal requires a lighter touch. These systems are suited for small cleaning jobs (like zinc coating or weld mark removal). These lower-powered, Q-Switched fiber-laser systems emit pulsing laser beams in preinstalled patterns (these patterns can be customized for specific applications). With Coating Strip Rates ranging from 6 to 24 ft2 per hr., these finishing class laser systems handle smaller projects with ease and produce a fine, texturized finish to the target surface. This makes them particularly suited for post-weld treatment and pre-coating surface preparation applications. In layman’s terms, Finishing Lasers’ processing capabilities can be most easily compared to:

- 20g to 30g Sheet Metal Gauge Numbers for Metal Fabricators

- #320 to #2000 Sandpaper Grit for Maintenance Shops

- 100 to 200 US CAMI Grit for Abrasive Blasting Contractors

- 600 dpi to 1200 dpi for Sign Makers

- 133 lpi to 200 lpi for Printing

Hopefully, this new Laser Grading system adequately addresses the issue of incongruence between a cleaning laser’s power and its performance—with relatable comparisons and understandable terminology for our customers in the industrial community.

About Laser Photonics Corporation

Laser Photonics is the leading industrial Brand in high-tech laser systems for laser marking, laser cutting, laser engraving, and other material processing applications. Our systems are currently and historically used by manufacturers in the automotive, aerospace, industrial, defense, electronic, semiconductor, flat panel, and medical industries around the world. The Laser Photonics Brand of products is associated with a number of worldwide licenses and patents for innovative and ‘unique to the industry’ laser products and technologies.

Laser Photonic’s brand history is associated with better throughput, higher quality, and low cost of ownership for each of our products. We are raising the standards and working toward making everyone’s life simpler through each laser application. The Brand has, for more than 2 decades, been the industry standard workhorse of laser subtractive material processing for such world-renowned companies such as Sony, NIKE, 3M, Delphi, NNSY-Norfolk Naval Shipyard, NASA, Cannon Air Force Base, Eaton Aerospace, GE, Caterpillar, Harley-Davidson, PPG, Eli Lilly, Smith & Nephew, Millipore, DuPont, Bosch, Gables Engineering, Champion Aerospace, Smith Aerospace, Metaldyne, Dupont and Heraeus. The present license holders are committed to continue the legendary performance of Laser Photonics Brand Equipment and provide award-winning support to its past, present, and future customers.