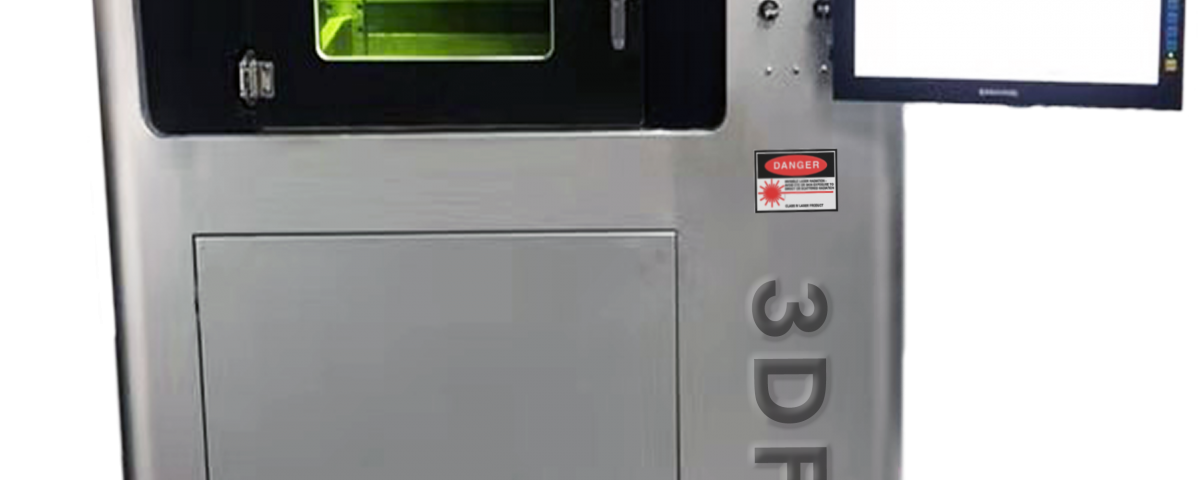

Dental 3D Printer

The 3DF-120D Dental 3D Printer is designed specifically for the dental industry to accommodate the price/performance requirements of the dental labs. The development of this new generation of affordable 3D printers brings a small footprint in a cost-effective way to produce high-quality prints.

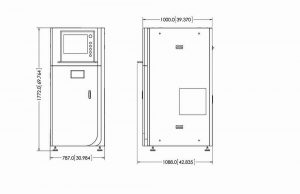

The 3DF-120D uses a printing chamber of 120x120x100mm, which allows the user to select between multiple print sizes. The system is built-in Laser Photonics’ conventional tower design when all controls located at the top of the system eliminating contamination of electronic components with metallic and conductive powder. The vertical build of the system allows for placement on a variety of workspaces or dental offices. With a low power consumption, the usage of conventional UPS provides continuous and non-interrupted operations for lengthy prints. Other features include cassette-to-cassette powder feeding and collection system and can be equipped with an inert gas handling module, depending on application needs.

| We Offer Our Customers… | |

|

|

- 3DF-120D FUSION Dental Laser Metal Printing System can print up to 160 crowns in 8 hour time frame.Compare to traditional casting process, 3D metal printed crown has better density and performance, achieving the density of 8.5g/cm3 – 8.65g/cm3.Advantages of 3D Metal Printed Crowns:

- Comfortable fit to individual tailored 3d denture geometry, no tilt of the crown during the fitting and fixing process.Excellent transition to gums along the dental crown borders.

- Inert Gas Recirculating

- Fiber Scan Fusion 3D Software

- Advanced Laser Fiber

- Re-circulation Chiller

Follow the link to download pdf file with systems specifications:

- 3D package for focal distance alignment without mechanical Z-axis

- Fiber Laser 100 watts or 200 watts

- 3D Head

Early 3D adopters of Laser Metal Printing for medical orthopedics benefit significantly from the ability of 3D Laser Metal Printing to manufacture complex geometries and structures with high grade NANO powders such as titanium. From patient-specific implants to ultimately, volume production of orthopedic implants featuring hybrid structures and textures; 3D Laser Metal Printing has the potential to unlock manufacturing capabilities that combine free-form shapes and intricate lattice structures that improve Osseo integration, leading to improved patient outcomes and reduced operating time-tables.

Visit Our Youtuber Channel.

- Industrial Vacuum Cleaner

- Glovebox cabinet

- Screening/Sieving Machine

- Sand Blaster

- Replacement gloves

- Vacuum Drying Oven

- Powder storage cabinet

- System Filters

- Powder Canisters

- 3D Scanner Arm

- 3D HandHeld Scanner