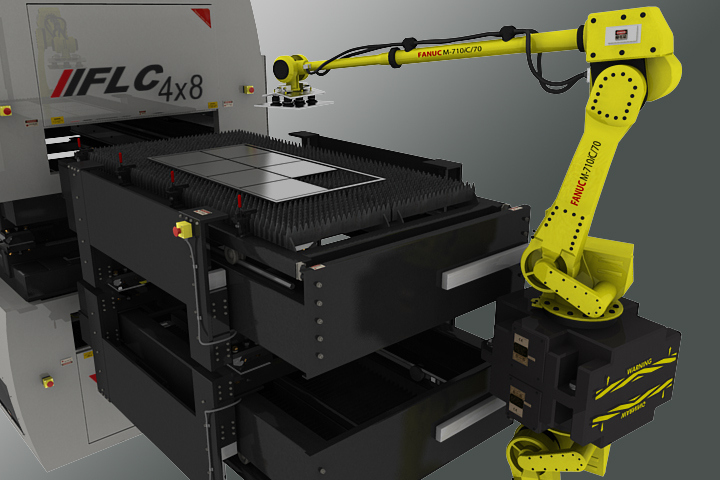

Titan Custom Laser

Custom Laser Cutting Equipment offers a fully-integrated system that monitors the cutting process and provides the user with relevant information. The high quality head ensures a processing with up to 15 kW of laser power and cut Stainless Steel for up to 40mm (1.5 “).

This high end laser cutting process can be utilized on single or dual shuttle table on a cutting systems ranging from 4′ x 8′ to 7′ x 13′ (2m x 4m).

Custom Laser Cutting System offers a complete solution for the laser-based cutting of thin, medium, and thick material thicknesses in the different types of metals from highly reflective (copper, brass, aluminum) to steel a, stainless steel, titanium, etc…

Cutting head is optimally converted into productivity, especially in the case of flatbed and pipe cutting machines, both 2D and 3D, where innovative technologies are combined with proven concepts, providing the best possible performance, range of flexibility and degree of reliability.

- motorized focus position adjustment for automatic machine setup and piercing work

- lightweight and slim design created for fast acceleration and cutting speed

- drift-free, fast-reacting distance measurement

- permanent protective window monitoring

- straight and angled design versions adapted to the machine concept

- completely dustproof beam path with protective windows

- LED operating status display

- display of operating parameters via Bluetooth® and interface for machine control

- pressure monitoring in the nozzle area (gas cutting) and in the head

- Cutting power up to 6 kW (with wave lengths of 1030 – 1090 nm)

- collimation length: 100 mm

- focus lengths FF: 125, 150, 175, 200 mm

- NAmax: 0.13

- dimension (WxD): 92 x 115 mm

- weight: 4.2 kg (FF125)

- Cutting Power up to 15 kW (with wave lengths of 1030 – 1090 nm

- collimation length FC: 100 mm

- focus lengths FF: 150, 200 mm

- NAmax: 0.13

- dimension (WxD): 92 x 115 mm

- weight: 4.9 kg (FF150)

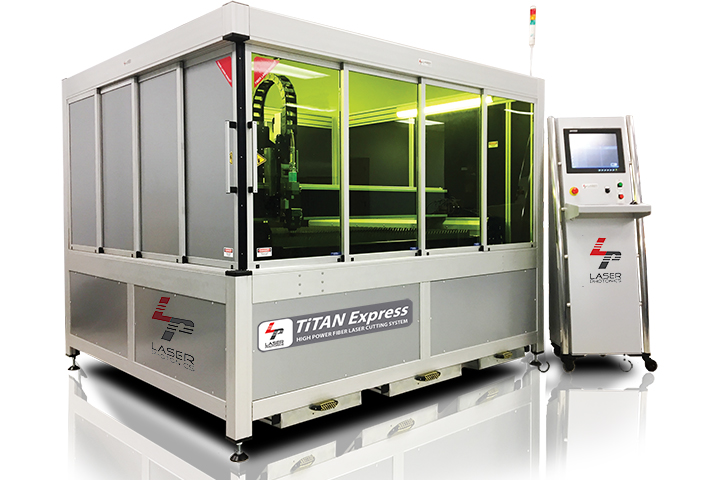

Titan Custom Laser

Custom Laser Cutting Equipment offers a fully-integrated system that monitors the cutting process and provides the user with relevant information. The high quality head ensures a processing with up to 15 kW of laser power and cut Stainless Steel for up to 40mm (1.5 “).

This high end laser cutting process can be utilized on single or dual shuttle table on a cutting systems ranging from 4′ x 8′ to 7′ x 13′ (2m x 4m).

Custom Laser Cutting System offers a complete solution for the laser-based cutting of thin, medium, and thick material thicknesses in the different types of metals from highly reflective (copper, brass, aluminum) to steel a, stainless steel, titanium, etc…

Cutting head is optimally converted into productivity, especially in the case of flatbed and pipe cutting machines, both 2D and 3D, where innovative technologies are combined with proven concepts, providing the best possible performance, range of flexibility and degree of reliability.

- motorized focus position adjustment for automatic machine setup and piercing work

- lightweight and slim design created for fast acceleration and cutting speed

- drift-free, fast-reacting distance measurement

- permanent protective window monitoring

- straight and angled design versions adapted to the machine concept

- completely dustproof beam path with protective windows

- LED operating status display

- display of operating parameters via Bluetooth® and interface for machine control

- pressure monitoring in the nozzle area (gas cutting) and in the head

- Cutting power up to 6 kW (with wave lengths of 1030 – 1090 nm)

- collimation length: 100 mm

- focus lengths FF: 125, 150, 175, 200 mm

- NAmax: 0.13

- dimension (WxD): 92 x 115 mm

- weight: 4.2 kg (FF125)

- Cutting Power up to 15 kW (with wave lengths of 1030 – 1090 nm

- collimation length FC: 100 mm

- focus lengths FF: 150, 200 mm

- NAmax: 0.13

- dimension (WxD): 92 x 115 mm

- weight: 4.9 kg (FF150)