Challenges in Laser Cutting Copper

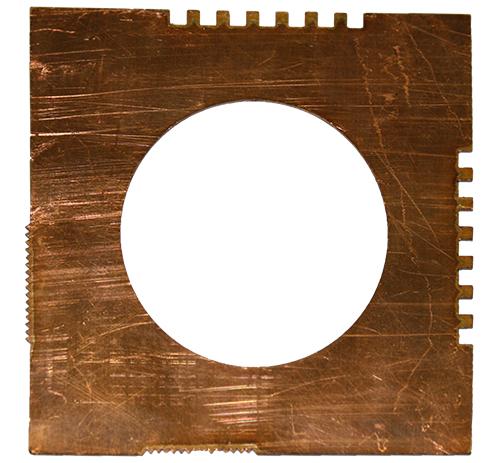

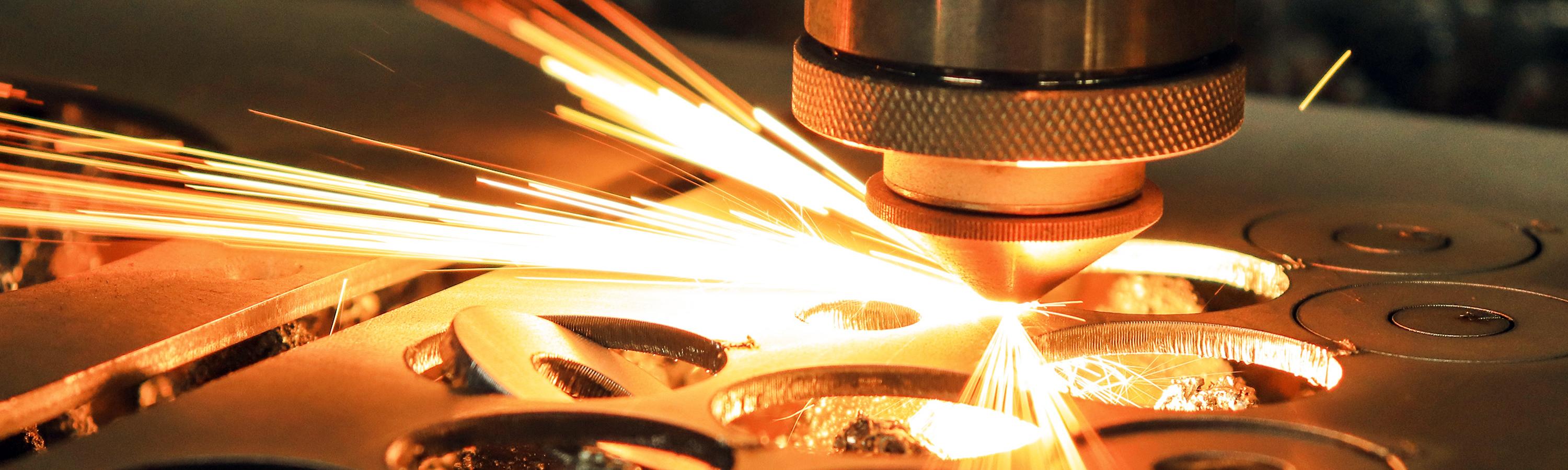

Copper is a highly reflective element. This made the cutting process difficult with conventional CO2 lasers because the laser beam reflects off the surface before the copper can absorb its energy. For this reason, manufacturers and fabricators chose alternative methods like water jets and stamping copper. However, innovations in fiber laser technology have made fiber laser machines ideal for this application. With a shorter wavelength, tighter focus, and greater power density, fiber lasers have become the best solution for cutting highly reflective materials like copper and brass.

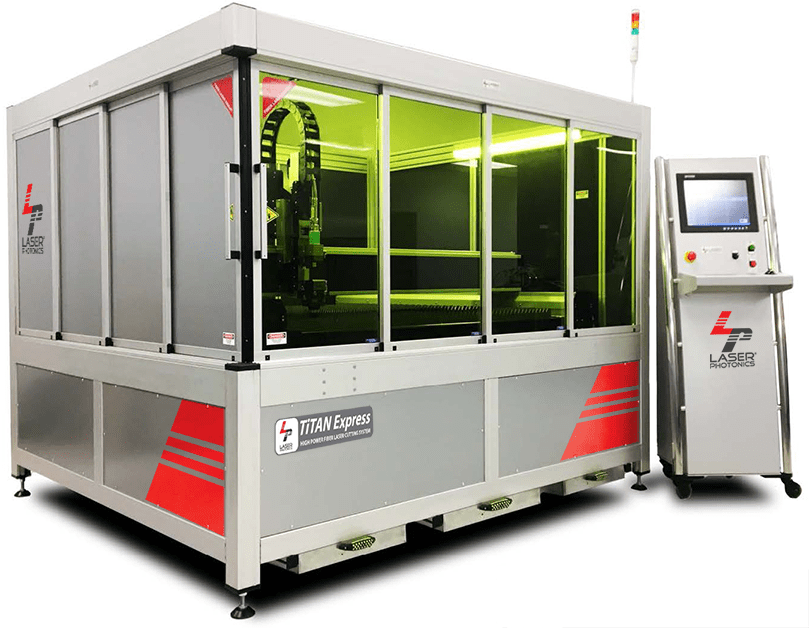

Recommended Laser Cutting Systems

About Laser Photonics Corporation

Laser Photonics Corporation, based in Orlando, Florida, is the leading industrial company in high-tech laser systems for laser cleaning, laser marking, laser cutting, laser engraving, 3D printing, and other materials processing applications. Our systems are currently and historically, used by manufacturers in the aerospace, automotive, defense, energy, industrial, maritime, and medical industries around the world. The Laser Photonics brand is associated with a number of worldwide licenses and patents for innovative and unique laser products and technologies. Laser Photonics has, for over three decades, been the workhorse of industry-standard laser subtractive manufacturing. Laser Photonics systems have been implemented into the production and maintenance regimens of world-renowned organizations such as Sony, NIKE, 3M, Delphi, NNSY-Norfolk Naval Shipyard, NASA, Cannon Air Force Base, Eaton Aerospace, Blue Origin, GE, Caterpillar, Harley-Davidson, PPG, Eli Lilly, Smith & Nephew, Millipore, DuPont, Bosch, Gables Engineering, Champion Aerospace, Smith Aerospace, Metaldyne, and Heraeus.