"Revealing Stellar Brilliance: Laser Precision for Space Exploration"

Laser Photonics researches and builds equipment to aid initiatives for space exploration. We address equipment that has the capability of improving efficiency, safety, inventory management, and more.

Laser Cleaning in particular is a new disruptive technology effectively replacing environmentally hazardous processes like sandblasting, chemical cleaning, or abrasive blasting – eliminating the health risks associated with sandblasting and chemical cleanings equipment. Lasers are applicable for contamination removal, surface restoration, and surface structure.

Laser Cleaning in the Space Exploration Industry

In the space exploration industry, lasers have found valuable applications in the cleaning and maintenance of critical components such as thrusters, nozzles, thermal tiles, fuel tanks, and hydraulic systems. Laser cleaning offers a non-intrusive and highly efficient method for structure restoration and for removing contaminants, oxidation, and debris from these vital spacecraft elements.

By harnessing the power of laser-induced plasma, high-energy laser beams can dislodge and vaporize unwanted substances without causing damage to the underlying surfaces. For thrusters and nozzles, laser cleaning ensures optimal performance by eliminating build-up that can obstruct exhaust flow and degrade thrust efficiency. In the case of thermal tiles, laser cleaning plays a crucial role in maintaining their insulating properties by preventing the accumulation of debris that could compromise heat resistance during re-entry. Laser cleaning also enhances the reliability and longevity of fuel tanks and hydraulic systems by removing particulate matter, rust, or corrosion that could lead to system malfunctions or clogging. It’s also used to remove the paint coating from all metal fixtures.

With its precision and effectiveness, laser cleaning has become an essential technique for maintaining the integrity and performance of critical components in space exploration missions.

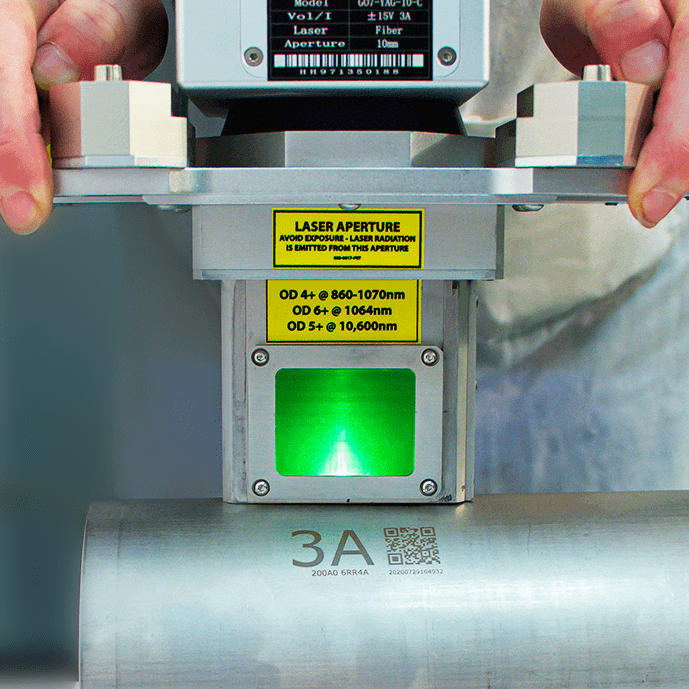

Laser Marking for permanent parts identification

Laser Marking has emerged as a valuable technique in the space exploration industry for labeling and tracking various components, including tiles and other vital parts. Laser marking utilizes high-energy laser beams to create permanent and precise markings on the surfaces of these materials. By engraving unique identifiers, such as serial numbers, barcodes, or logos, onto tiles and other parts, laser marking enables efficient identification and traceability throughout the lifespan of a spacecraft.

These markings play a crucial role in inventory management, quality control, and maintenance procedures, ensuring accurate tracking of components during assembly, testing, and deployment. Laser marking offers several advantages, including high-speed processing, durability, and the ability to mark on various materials, including metals, ceramics, and composites. With its ability to withstand extreme temperatures, vacuum conditions, and harsh environments, laser-marked information remains legible and intact throughout the rigors of space exploration.

Overall, laser marking has become an indispensable tool in the space industry, facilitating efficient component identification and traceability, and enhancing the overall safety and reliability of space missions.

Laser Cutting of fuel tanks, latches and other critical components

Laser Cutting has revolutionized the manufacturing and maintenance processes in the space exploration industry, particularly in the fabrication and modification of fuel tanks and latches. With its high precision and versatility, laser cutting enables the precise shaping and resizing of fuel tanks to meet specific mission requirements. The intense and focused laser beam can swiftly cut through various materials used in fuel tank construction, including metals and composites, without compromising their structural integrity. This allows for the creation of intricate designs, optimized shapes, and precise dimensions, ensuring efficient fuel storage and distribution.

Laser cutting also plays a critical role in the fabrication of latches and fasteners used in securing fuel tanks and other components. The laser’s ability to precisely melt, vaporize, or remove material enables the production of complex latch mechanisms with tight tolerances, promoting reliable and secure connections. Furthermore, laser cutting offers benefits such as minimal heat-affected zones, reduced material waste, and improved production speed compared to traditional cutting methods.

Through laser cutting, the space exploration industry achieves enhanced fuel efficiency, improved structural integrity, and streamlined manufacturing processes for fuel tanks and latches, contributing to the success of space missions.

Laser Welding in the Space Exploration industry

Laser welding has emerged as a vital technique in the space exploration industry, facilitating the construction and repair of critical components with unparalleled precision and strength. The focused and high-energy laser beam creates localized heat, melting and fusing materials together without the need for additional filler materials. This enables the seamless joining of various metals and alloys used in spacecraft construction, ensuring robust and durable connections.

Laser welding is particularly advantageous in the space industry due to its ability to produce strong and reliable welds in challenging conditions, including vacuum environments and microgravity. It allows for precise control over the welding process, resulting in minimal distortion and heat-affected zones, which are crucial for maintaining the structural integrity of spacecraft.

Moreover, laser welding offers increased efficiency and productivity, with its ability to automate and perform intricate welds with high repeatability. Whether it’s the fabrication of complex structural elements or the repair of damaged components, laser welding plays a pivotal role in advancing space exploration by providing strong, reliable, and efficient joining solutions.

Laser Quartz Welding is a technology used in the manufacturing process of the opening windows of space telescopes.

Robotic Automation

Any of our laser applications can be easily integrated into your production line via robotic automation to generate repeatable and nearly perfect results.