Laser Photonics Corporation engineers and constructs industrial-grade laser systems that use the latest in fiber laser technologies to drive material processing techniques in the semiconductor and flat panel display industry.

Laser Photonics has demonstrated revolutionary advancements in laser material processing over existing technologies. These advancements translate into numerous cost and performance benefits in a multitude of industries for wafer dicing, flat-panel separation, silicon cutting, and direct parts marking used in semiconductor, solar energy, military and defense, flat panel display, automotive, medical, electronics, ceramic and aerospace industries. Laser Photonics has also developed state-of-the-art laser cutting and engraving systems combining flying optics with precision direct drive motion systems for multipurpose cutting and engraving.

Our ZWLC® (Zero Width Laser Cutting) will cover unprecedented explosive growth and demand in semiconductor markets in China, Taiwan, Japan and Korea. Our unique position and current product recognition in the FPD market worldwide will give us a head-start to become a leader in the FPD and semiconductor industries. A recent change in market disposition opens for Laser Photonics product a wide road to a quarter-billion dollar wafer dicing industry.

Semiconductor Laser Systems

SBM777 Ceramic Scriber

The SBM777 is an industrial laser scribing system designed for ceramic applications. The system can be configured with single or double CO2 or fiber laser heads for increased throughput. Our “plug-n-play” modular system makes the SBM777DC extremely simple to operate and maintain.

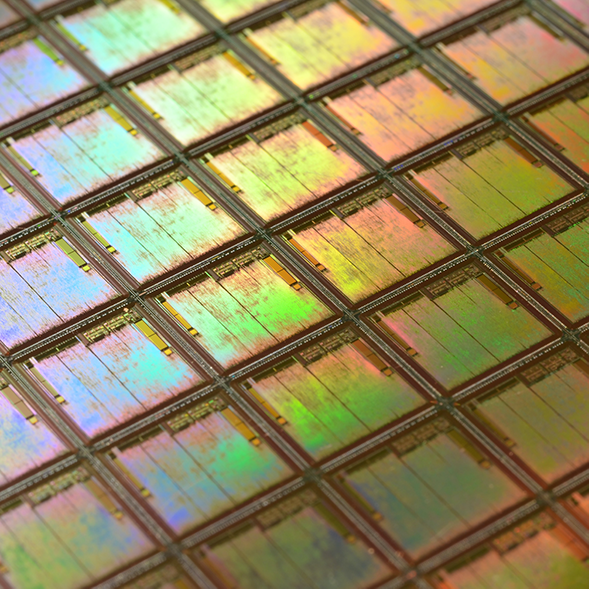

Blackstar™ Wafer Dicing System

The Blackstar utilizes zero-width laser cutting technology to dice silicon wafers at the molecular level to increase the dies per wafer. The Blackstar is capable of dicing a wide variety of materials such as silicon, gallium arsenide, germanium, indium phosphide, silicon carbide, and more.