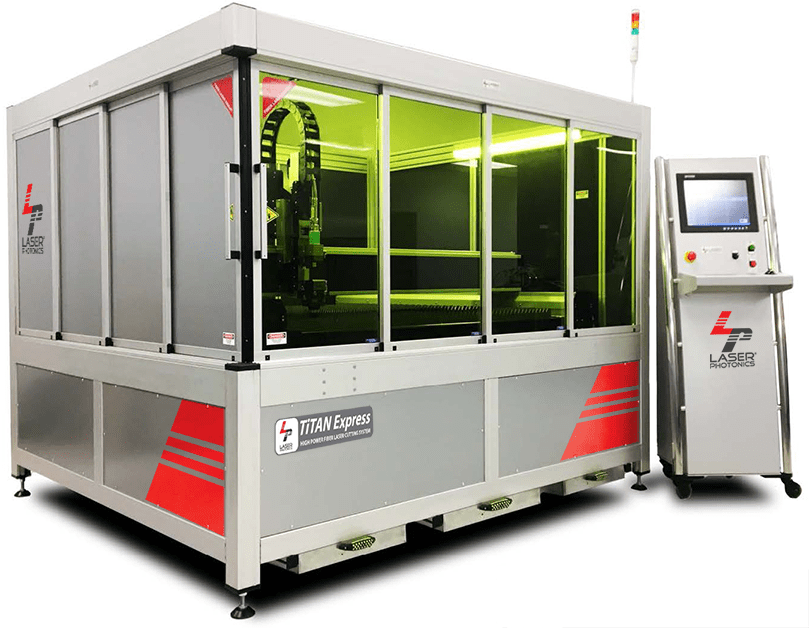

Titan Express Laser Cleaning System

Mid-Size – Powerful – Complete. The CleanTech Titan Express Laser Cleaning Machine is a midsize, high power, large format fiber laser cleaning and surface conditioning system with up to 4′ x 4′ working envelope. The industrial-grade full-featured laser cleaning system that fits within your floor space and your budget.

CleanTech Laser Systems offer a non-abrasive cleaning system that is safer, easier, and more eco-friendly than traditional methods of surface cleaning. Incorporating proprietary Flexion Technology allows CleanTech Systems to clean materials faster and more efficiently than other systems on the market. Flexion Technology offers a motion control stage that operates in both the X and Y-axis. This allows the laser to move in various directions and clean nested parts under the path of the trajectory beam. This unique technology allows the laser to clean all sides of any part.

Support & Training Available to Customers

- Factory and on-site operator training

- Advanced customer training

- Designated customer service engineers

- Optimal system configuration

- Inbound Customer Support

- Advanced application support

- Notifications of system upgrades

- Remote diagnostics capability

- Direct Technical Support

- Engineers log for testing and troubleshooting

- And More

Interested in Financing?

Need a Laser? Let Us Help! Speak to an Expert Today.

Some of the features and benefits of the CleanTech Titan Express include a direct drive motion system, large format cleaning (allows for applications such as cleaning automotive tire rims, mold cleaning, phalanges for the oil and gas industry, or even sheets for a hull) mid-size footprint, high power – low energy fiber laser, Flexion Technology and industrial-grade reliability with an MTBF of 100,000 hours.

Included in the CleanTech product line are the CleanTech Titan, CleanTech Megacenter, and the portable CleanTech Handheld which is useful in the field or on the factory floor. Made in the USA, the CleanTech Systems operate with full compliance to OSHA, FDA, CDRH conforming to “Push a Button” laser safety industrial operation. The CleanTech Systems offer CE Certified Class 1 enclosure for the Class 4 lasers. Additionally, CleanTech has an integrated dust and residue collection system and can allow for a 3D scanner option to clean parts with complicated shapes.

To Learn More About This Product Please Contact Laser Photonics

|

|

|

|

|

|

|

|

|

|

|

|

To Learn More About This Product Please Contact Laser Photonics

To Learn More About This Product Please Contact Laser Photonics

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|