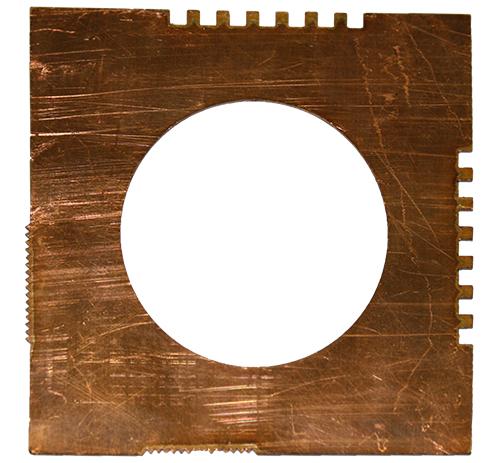

Laser Cutting Copper

Challenges in Laser Cutting CopperCopper is a highly reflective element. This made the cutting process difficult with conventional CO2 lasers because the laser beam reflects off the surface before the copper can absorb its energy. For this reason, manufacturers and fabricators chose alternative methods like water jets and stamping copper. However, innovations in fiber laser technology have made fiber laser machines ideal for this application. With a shorter wavelength, tighter focus, and greater power density, fiber lasers have become the best solution for cutting highly reflective materials like copper and brass.

Laser Cutting Copper Samples

Recommended Laser Cutting Systems

About Laser Photonics Corporation

Laser Photonics Corporation, based in Orlando, Florida, is the leading industrial company in high-tech laser systems for laser cleaning, laser marking, laser cutting, laser engraving, 3D printing, and other materials processing applications. Our systems are currently and historically, used by manufacturers in the aerospace, automotive, defense, energy, industrial, maritime, and medical industries around the world. The Laser Photonics brand is associated with a number of worldwide licenses and patents for innovative and unique laser products and technologies. Laser Photonics has, for over three decades, been the workhorse of industry-standard laser subtractive manufacturing. Laser Photonics systems have been implemented into the production and maintenance regimens of world-renowned organizations such as Sony, NIKE, 3M, Delphi, NNSY-Norfolk Naval Shipyard, NASA, Cannon Air Force Base, Eaton Aerospace, Blue Origin, GE, Caterpillar, Harley-Davidson, PPG, Eli Lilly, Smith & Nephew, Millipore, DuPont, Bosch, Gables Engineering, Champion Aerospace, Smith Aerospace, Metaldyne, and Heraeus.

Need A Laser? Let Us Help

First Name (required)

Last Name (required)

Email

Company

Phone Number

Δ

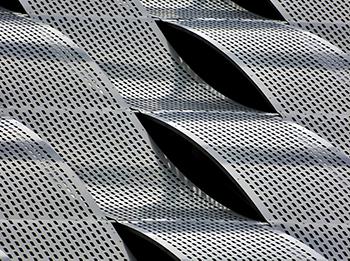

Laser Cutting Stainless Steel

Stainless steel is fabricated across almost every industry. Conventional methods include CO2 laser cutting, plasma, water jet, sheering, punching and stamping. Cutting with a Fiber laser can eliminate almost every other method. With the speed of linear motors and the power of a Fiber laser cutting up to 1”, almost every method of fabricating stainless steel becomes obsolete. Although other lasers can cut thick stainless steel, Fiber technology is extremely efficient, reliable and relatively zero maintenance. This positions Fiber laser cutting as the preferred method over conventional technologies.

Click on images below to enlarge

About Laser Photonics Corporation

Laser Photonics Corporation, based in Orlando, Florida, is the leading industrial company in high-tech laser systems for laser cleaning, laser marking, laser cutting, laser engraving, 3D printing, and other materials processing applications. Our systems are currently and historically, used by manufacturers in the aerospace, automotive, defense, energy, industrial, maritime, and medical industries around the world. The Laser Photonics brand is associated with a number of worldwide licenses and patents for innovative and unique laser products and technologies. Laser Photonics has, for over three decades, been the workhorse of industry-standard laser subtractive manufacturing. Laser Photonics systems have been implemented into the production and maintenance regimens of world-renowned organizations such as Sony, NIKE, 3M, Delphi, NNSY-Norfolk Naval Shipyard, NASA, Cannon Air Force Base, Eaton Aerospace, Blue Origin, GE, Caterpillar, Harley-Davidson, PPG, Eli Lilly, Smith & Nephew, Millipore, DuPont, Bosch, Gables Engineering, Champion Aerospace, Smith Aerospace, Metaldyne, and Heraeus.

Need A Laser? Let Us Help

First Name (required)

Last Name (required)

Email

Company

Phone Number

Δ

Laser Cutting Aluminum

Aluminum is widely used in metal fabrication but not exclusively cut by lasers. Aluminum is extremely reflective to conventional CO2 laser technology. Fiber lasers are the answer. Fiber lasers have a shorter wavelength and greater power density. This enables fiber lasers to cut up to 1” aluminum and penetrate a market in which plasma and water jet ruled.

Click on the image to enlarge

Recommended units: FLC >2kW

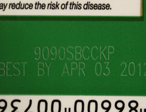

Fiber Laser Etching

This process is commonly used to create permanent part marking. Etching is typically a very shallow surface removal to create contrast. Applications range from etching electronics, tools and automotive components.

Click on image to enlarge

Laser Processing & the Packaging Industry

Laser processing has only recently started to take hold of the packaging industry. Newer laser technology has finally met the high throughputs that older technology, like ink jet and stamping, had set the standards within automated lines. Laser processing is ideal for the high speeds and repeatability that the packaging industry requires. Laser Photonics systems can be seen in bottle marking lines, boxes, label making, and other consumable packaging products.

Laser Processing in the Firearm Industry

ATF regulations have led the firearms industry to seek laser solutions. With high peak power systems now available, firearm manufactures are able to meet ATF standards while manufacturing 24/7 with zero down time for maintenance or retooling. Laser Photonics’ Canyon Deep Engraving system was specifically designed to meet the performance demands of the leaders in the firearms industry.

114

The miscellaneous glass marking application was done using a Synrad 48-2 25 watt CW CO2 laser with a FLA125 focal length lens. The glass was marked using a power of 25 watts at a speed of 25” per second, resulting in a cycle time of 0.52 seconds. The font was a simple stroke. The material provided readable marks.

131

This titanium sample was marked using laser abblation with 16 watts of power resulting in very high quality dark marks at 5.98 (larger logo) and 4.21 (smaller logo) cycle times. Technology: Q-switched Fiber Laser, Wattage: 20 Watt Focal Length Lens: 160mm.

147

These ceramic medical parts were laser marked using a 20 Watt Fiber Laser Marking System.

163

The aluminum was marked with a 20-watt q-switched ytterbium fiber laser with a 160 mm focal length lens. The part was surface etched, to create a highly contrasting mark. The part was marked at 35 inches per second using approximately 16 watts with a frequency of 35 kHz, resulting in a cycle time of 16.32 seconds.

180

Company: CAT

The samples marked extremely well with the 20-watt Fiber Laser Marking System. Dark marks were placed on the steel tappets. The steel tappets had a cycle time of 7.73 seconds. A high frequency was used to get dark marks on steel.

115

Glass marking was done with a Synrad 48-2 25 watt CW CO2 laser with a FLA125 focal length lens. The glass was marked using a power of 25 watts at a speed of 25” per second, resulting in a cycle time of 0.52 seconds. The font was a simple stroke. The material provided readable marks.

132

The parts were marked with a 10-watt q-switched ytterbium fiber laser and a 160 mm focal length lens. The 160mm focal length lens has a working distance of 176mm from lens to part. The parts were surface marked to created contrast on the samples. The titanium piece was marked with a cycle time of 9.36 seconds.

148

The parts were marked with a 10Watt Fiber Laser Marking System using a 160 mm lens. The parts were marked with both an etched mark as per the enclosed sample. The 2D code was marked off the edge as requested. The cycle time for the text along with the 2D code was 2.21 seconds.

165

UID marking was accomplished with a 20-watt q-switched ytterbium fiber laser with a 160 mm focal length lens. The small gear sample was marked on both sides. The side with the etched mark had a cycle time of 0.977 seconds. The side with the dark anneal mark had a cycle time of 6.33 seconds. All the 2D codes on the samples read at the lab.

181

Caterpillar Sample Parts Marking

The samples marked extremely well with the 20-watt Fiber Laser Marking System. Dark marks were placed on all of the steel tappets. The steel tappets had a cycle time of 7.73 seconds. A high frequency was used to produce dark marks on steel.

116

Laser marking application of a stainless steel medical grade ruler. The sample marked extremely well with the 20-watt Fiber Laser Marking System. See the Fiber Tower series for more details.

133

The parts were marked with a 10-watt q-switched ytterbium fiber laser and a 160 mm focal length lens. The parts were surface etch, to create contrast. Some of the material was not able to mark well.