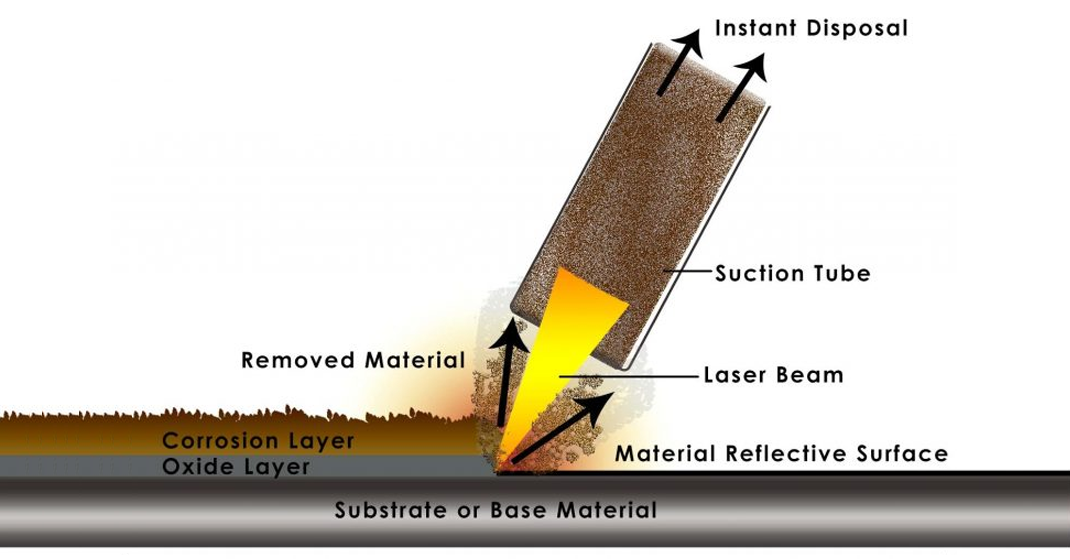

Fiber Laser Cleaning Technology is a proven, state-of-the-art solution for the 21st Century. It works by aiming brief pulses of high-power laser energy (in the µs–ms range) at the surface to be cleaned. The energy applied to the top layer being removed doesn’t dissipate. Instead, it blasts off the material being cleaned through the process known as laser ablation. For example, the Laser Photonics 2000-CTH-Jobsite uses a 2000W fiber laser to break the molecular bonds between the corrosion and the substrate, which in turn vaporizes contaminants through sublimation, leaving the surface untouched. Any remaining removed material may be suctioned and collected into a filtration as particle dust.

Laser Photonics leads the way with technologies such as CleanTech™ Laser Blasting™. Laser Blasting (a.k.a. Laser cleaning and laser ablation) is a non-contact, environmentally friendly process that removes surface coatings from metals, concrete and delicate substrates such as composites – with minimal impact on the base material. Laser Blasting can replace sandblasting or dry ice blasting in nearly every industry and every application where abrasive blast cleaning is used. It is effective on glass, ceramics, metals, composites, plastics, and much more, and provides greater control and precision than possible with the legacy technologies it is designed to replace. LP portable Laser Blasting systems expand cleaning from the floor to the hangar, and beyond. Laser Blasting is being applied to fuselages, airfoils, control sources, turbine blades, and rocket engine nozzles, as well as small parts and sensitive materials.

1. Addresses Worldwide EPA and Chemical Containment Issues

Dispersed debris during cleaning processes is controlled and collected to reduce air pollution in the work areas, frequently a problem with abrasive blasting and chemical etching.

2. Fast Removal, Quality Finish

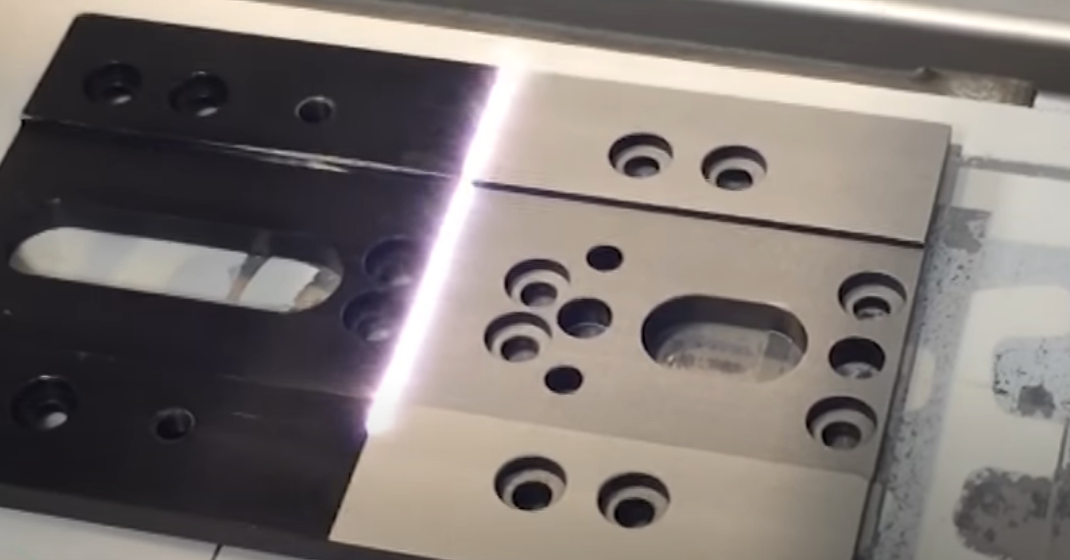

The 2000-CTH Jobsite is the most powerful laser cleaner available that delivers short and strong power bursts ensuring the most consistent beam path for faster removal and consistent cleaning quality.

3. Reduces Base Material Damage/Reduction Risks

Utilizing Cleantech™ Technology, the laser can selectively remove layers in an efficient and safe way to protect base materials.

4. Versatile Industrial Applications

This new technology can be used for a variety of material processing needs within various industries with high-temperature and high-pressure environments such as aerospace, automotive, military & defense, power generation, nuclear facilities, and maintenance & repair facilities.

5. Eco-Friendly Technology

Cleantech™ Laser Cleaning Technology allows the laser cleaning process to be environmentally-friendly by being consumable-free.

6. Maintenance Free

Our laser systems generally require no optical machine alignment, laser service, or laser replacement parts making this machine virtually maintenance-free.

7. Meets OSHA Compliance Regulations

All machines from Laser Photonics can meet laser compliance, EPA, and OSHA regulations.

8. Versatile Uses: Cleans, Prepares, and Primes

Cleantech™ can clean, ablate, prepare, and prime surfaces such as aluminum, anodized aluminum, alloy metals, stainless steel, mild steel, copper, brass, non-transparent plastics, plaques, and more.

9. High Power – Low Cost

This machine offers ultra-low power consumption allowing for the lowest operating costs among all laser types.

10. SPEED!

Not comparable to other handhelds, the 2000 CTH has a lighter weight design and the fastest cleaning speed in the market. View the 2000-CTH Jobsite in action as we remove rust from steel. Laser Photonics also provides a variety of fiber and CO2 laser strengths (100W, 200W) to complete any job.

Stay Up to Date With Laser Photonics

About Laser Photonics

For over 35 years, Laser Photonics has been leading the way in innovative fiber laser and CO2 laser machines. Laser Photonics specializes in developing laser marking, laser cutting, laser cleaning, and laser engraving machines for precision material processing industries. Their laser machines are used by fortune 1000 manufacturers in automotive, aerospace, industrial, defense, electronic, and medical industries around the world and meet all laser compliance regulations. Our mission is to help minimize chemical and abrasive usage to improve industrial manufacturing environments and meet demanding industrial compliance regulations.